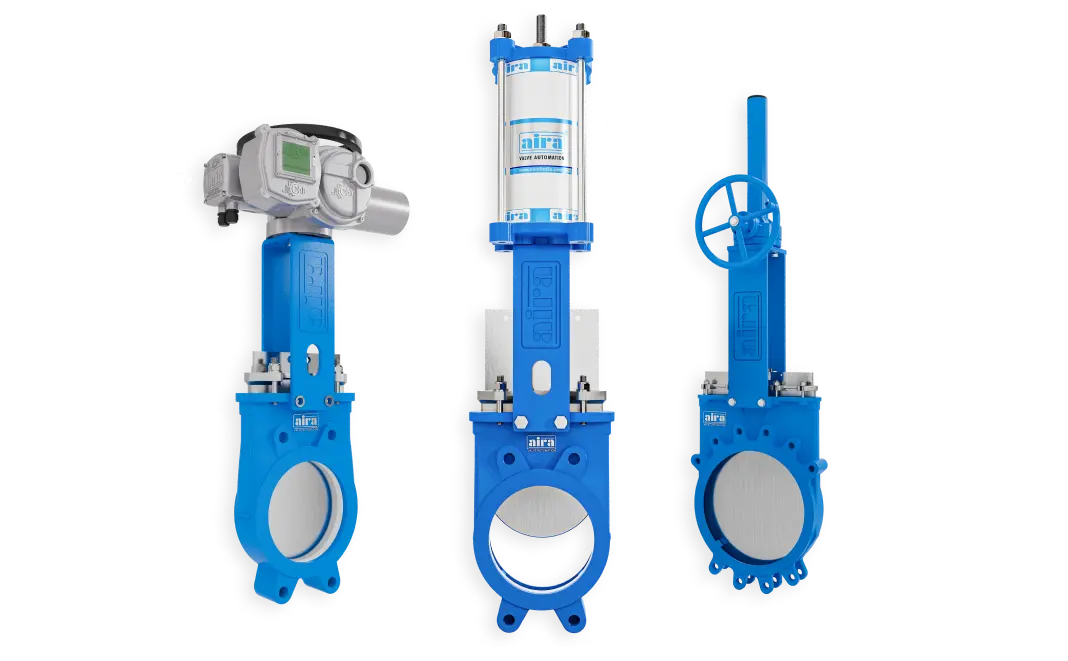

Aira Euro Automation is a prominent Knife Edge Gate Valve Manufacturer, Supplier, and Exporter in India. We have a highly experienced team of engineers, who always work to build easy to use, safe, and quickly operated valves.

We generally confirm to MSS SP 81 to follow manufacturing standards, we use IS 210 Gr. FG200 S.Steel 304 material for Valve Body, AISI 304 SS material for Trims, and CF8 / CF8M / CF3M material for Bonnet.

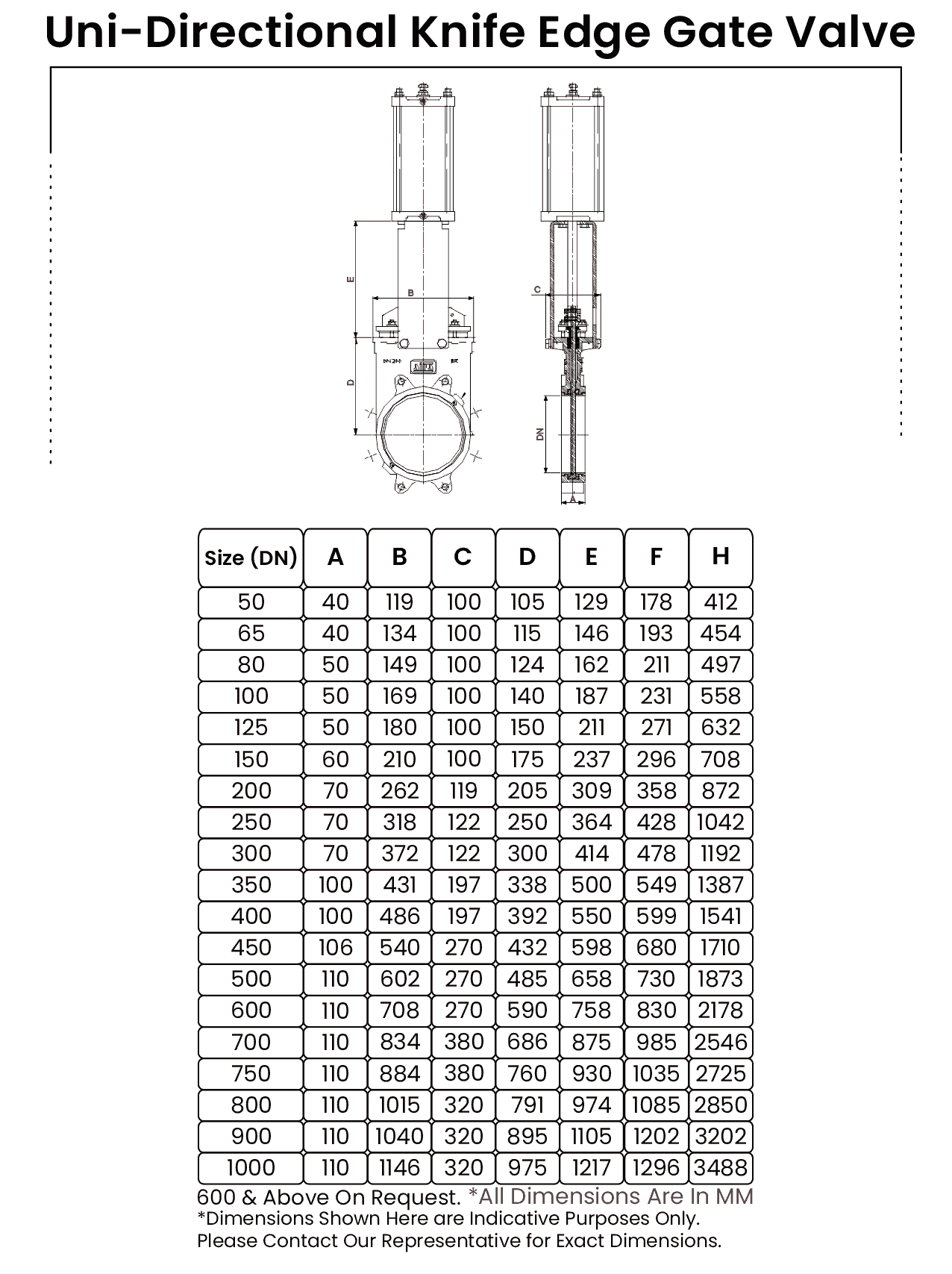

This valve has Metal to Metal / NBR seals, the available size range is 2” to 24” and Max. C.W.P. is 100 PSIG (7 Kg/cm2). It comes up with Lug Type Suitable For BS 10 Table “D” / ANSI B 16.1 (125#) End connections with Class IV to V Leakage Class.

For pneumatic cylinders we use Aluminium / S.Steel to make Barrel, Aluminium Pressure Die Cast / C.I. to make End cover, Stainless Steel for Piston Rod, and for Seals, we use Nitrile and also Viton on Request.