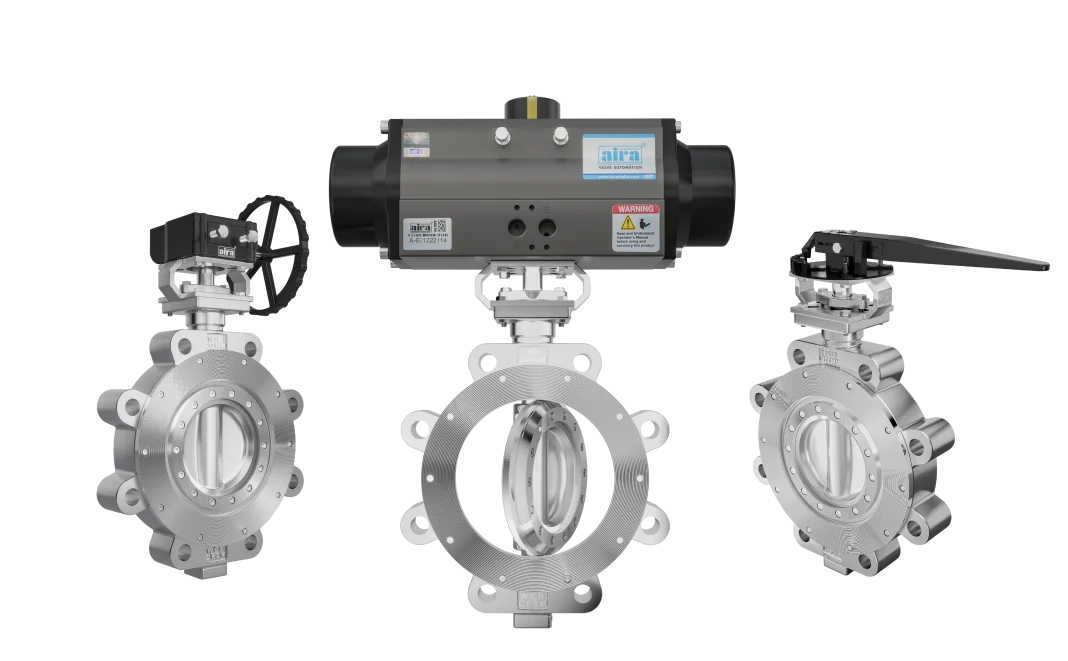

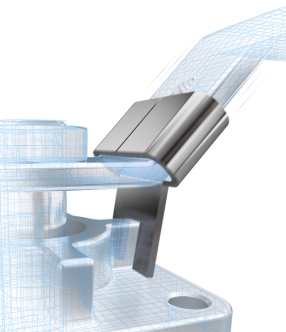

A Triple Offset Lug Type Butterfly Valve features a unique design with three offset points, ensuring a tight seal and preventing seat wear. It is used to control the flow of fluids in pipelines and is ideal for high-pressure and high-temperature applications. The lug-style design allows for easy installation and maintenance, making it a reliable choice for industries such as oil and gas, water treatment, and chemical processing.

Approvals

Specification & Standard

Design & Manufacturer

API 609 Category "B"/BS EN 593

Valve Face To Face Dimension

API 609/BS EN 558

Flange Standard Conformity

ANSI B16.5, 16.47 150#/300#/600#

Inspection & Testing

FCI-70-2/ B16,104/ ISO 5208/ BS EN 12266-1

Pressure Temperature Rating

ASME B 16.34

Top Mounting Standard

ISO 5211

Stem Square Drive

ISO 5211

Seat Leakage Class

IV/ V/ VI

Top Flange Drilling

ASME B16.5/ 16.47 Class 150.

End Connection

Wafer Type- D/F- AWWA C 504 D/F - IS 13095 - 150# 300# 600# PN-10 PN-16 PN-20 PN-25 PN-40

Size Range

1.1/2" To 24" (Above 24" On Request) (40 MM To 600 MM)

Tepreature Range

Upto 400°C

Pressure Class

150#, 300#, 600# PN-10 PN-16 PN-20 PN-25 PN-40

Media

Water, Oil, Steam , Air, Gas Chemical & Vaccum.

Leakage Class

Class VI As Per ANSI B16.104

Body Material

CI, DI, S.G.I, WCB, CF8, CF8M, CA15, WCC, LCB, WC6, WC9, WC12, HAST ALLOY C, NICKEL ALUMINIUM BRONZE, DUPLEX 4A, 5A, 6D, SUPER DUPLEX, ALLOY 20

Disc Material

CI, DI, S.G.I, WCB, CF8, CF8M, CA15, WCC, LCB, WC6, WC9, WC12, HAST ALLOY C, NICKEL ALUMINIUM BRONZE, DUPLEX 4A, 5A, 6D, SUPER DUPLEX, ALLOY 20

Seat Material

SS 304 , SS 304L, SS 316, SS 316L, SS 304 + STALLITE 6, SS 316 + STALLITE 6, SS 316 + STALLITE 21, SS 316 + STALLITE 21, INCONEL, DUPLEX 4A, DUPLEX 5A

Certification

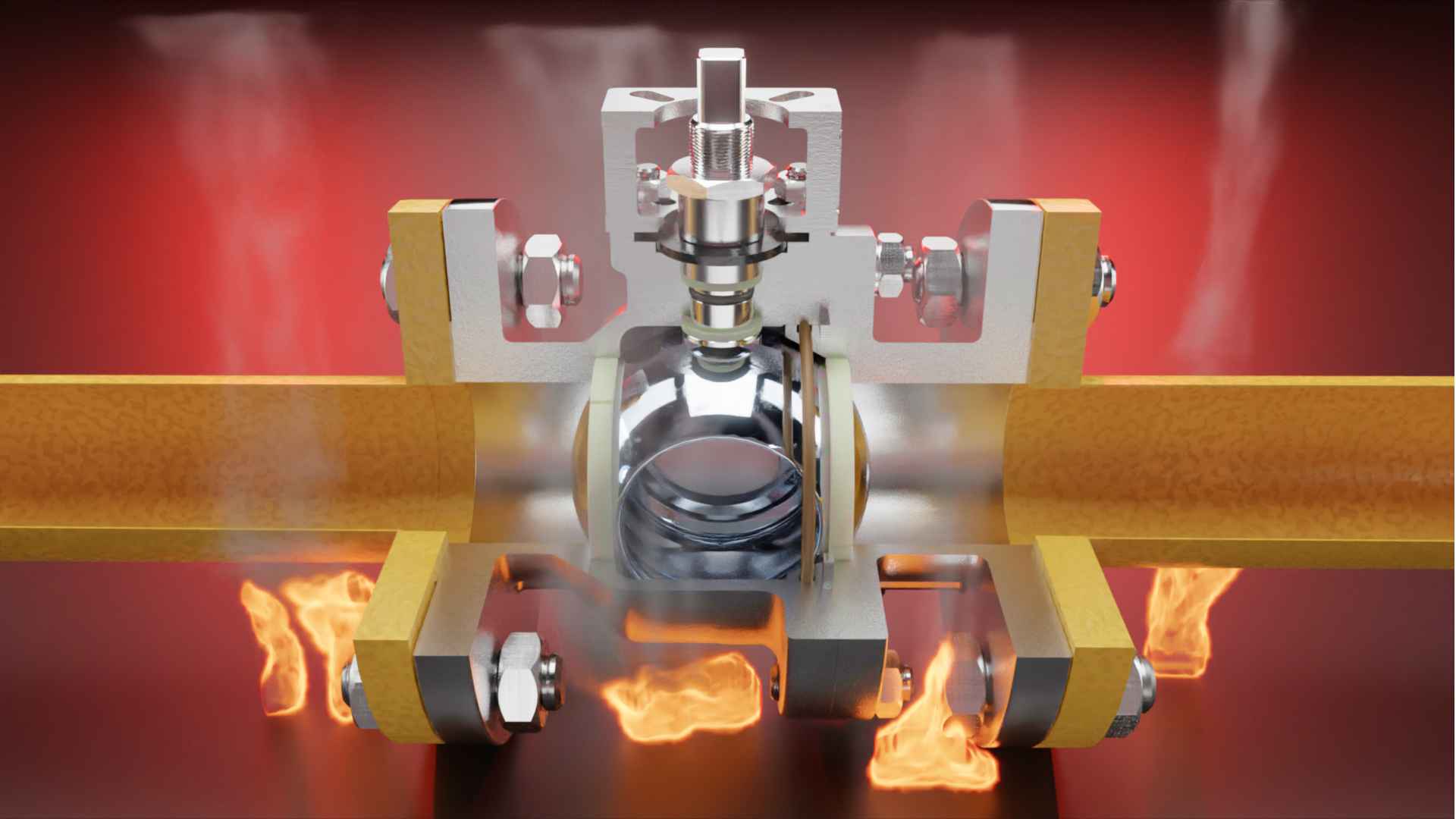

Design CE Approved, SIL3 Approved, Fire Safe Design Approved

The aira Triple Offset Lug Type Butterfly Valve is engineered for high performance and reliability in demanding applications.

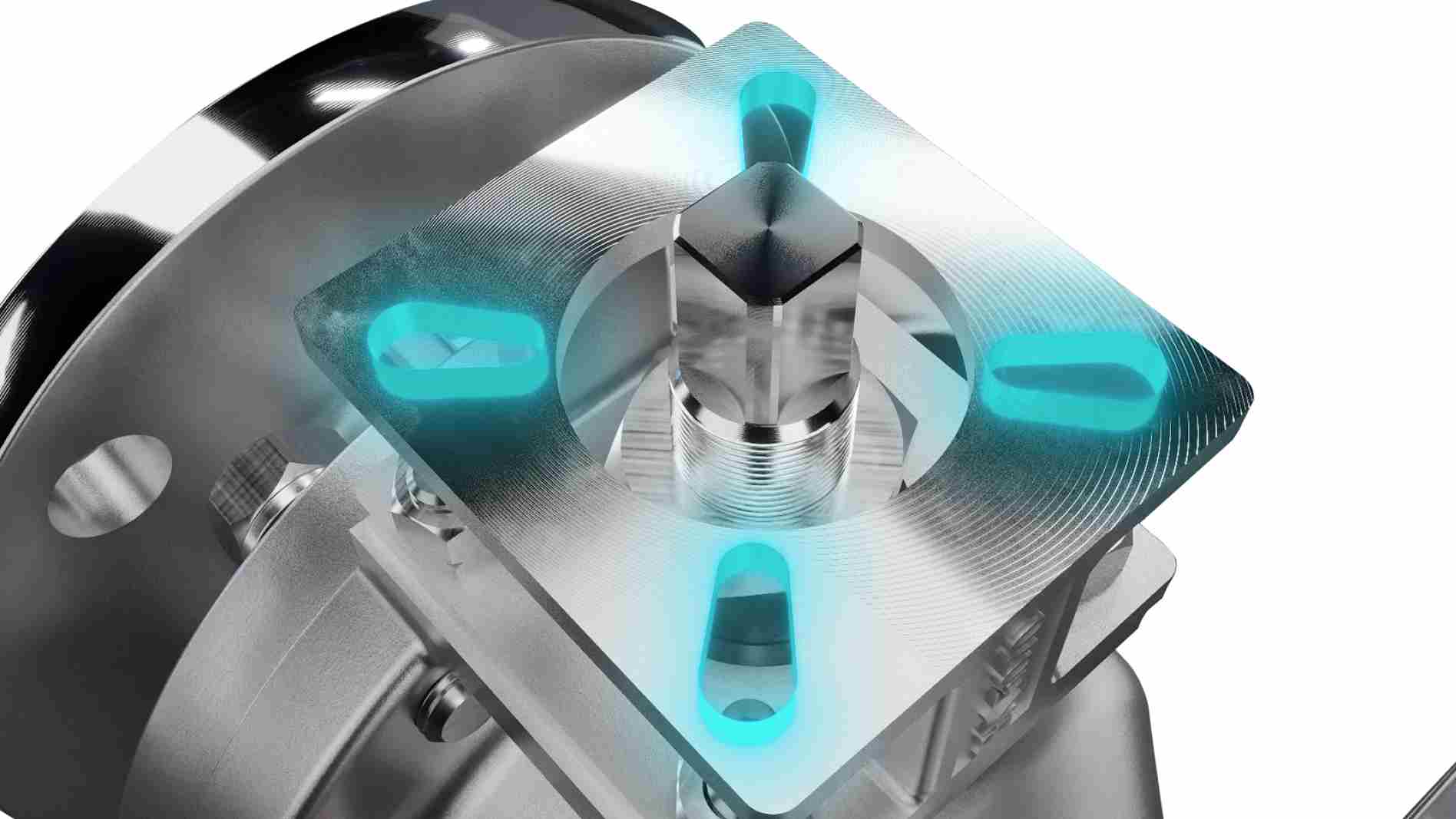

1 – Triple Offset Design: Provides excellent sealing and minimizes friction, ensuring a tight shut-off and reducing torque requirements.

2 – Lug Style: Designed with integrated lugs for easy mounting and dismounting between flanges, facilitating straightforward installation and maintenance.

3 – Robust Construction: Built from high-quality materials to endure extreme conditions and high pressures.

4 – Enhanced Sealing: Advanced sealing technology minimizes leakage and enhances operational reliability.

5 – Versatile Use: Ideal for various industrial applications, including water treatment, chemical processing, and power generation.

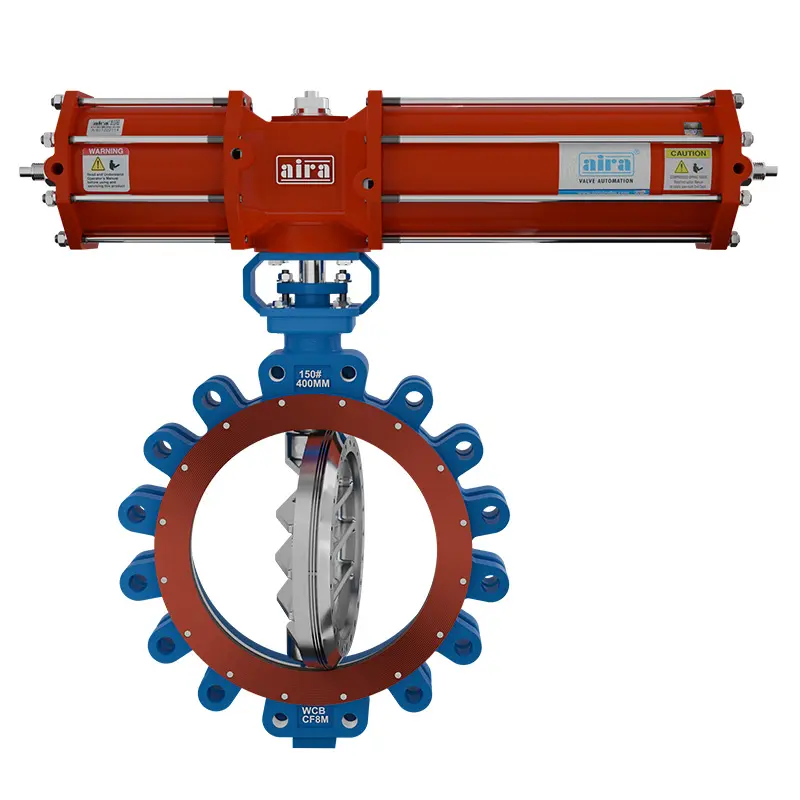

For your ease and safety, aira euro has manufactured a Pneumatic Rotary Actuator Operated Triple Offset Lug Type Butterfly Valve with Fire safe design to prevent accidents in your work area.

Materials:

We use ASTM A 216 Gr. WCB A 351 Gr. CF8 / CF8M / CF3M casting material for Body, AISI 410 / 304 / 316 for Shaft, ASTM A 351 Gr. CF8 / CF8M / CF3M for Disc, and Metal to Metal / EPDM material for Seat.

Specialty:

This valve is available in 1.½” to 48” in size can easily sustain pressure up to 10 BAR and temperature up to 120°C in EPDM material and 300°C in Metal to Metal. It comes up with VI leakages as per ANSI B 16, 16.104, and Lug type End connections.

Where to use:

These valves are useful to control the flow of Oil/ Gas/ Steam/ Water/ Air/ Chemical & Vacuum. So it is very useful in Oil refineries, Petro- Chemical Plants, Gas Plants, etc.

Tripple Offset

Lug Type Butterfly Valve

Tripple Offset

Lug Type Butterfly Valve

Dimension Table

ADDONS

Related Products

Working Days: Monday to Saturday.Tell Us How We Can Help You

Request A Quote

Complete control over products allows us to ensure our customers receive the best quality prices and service