Approvals

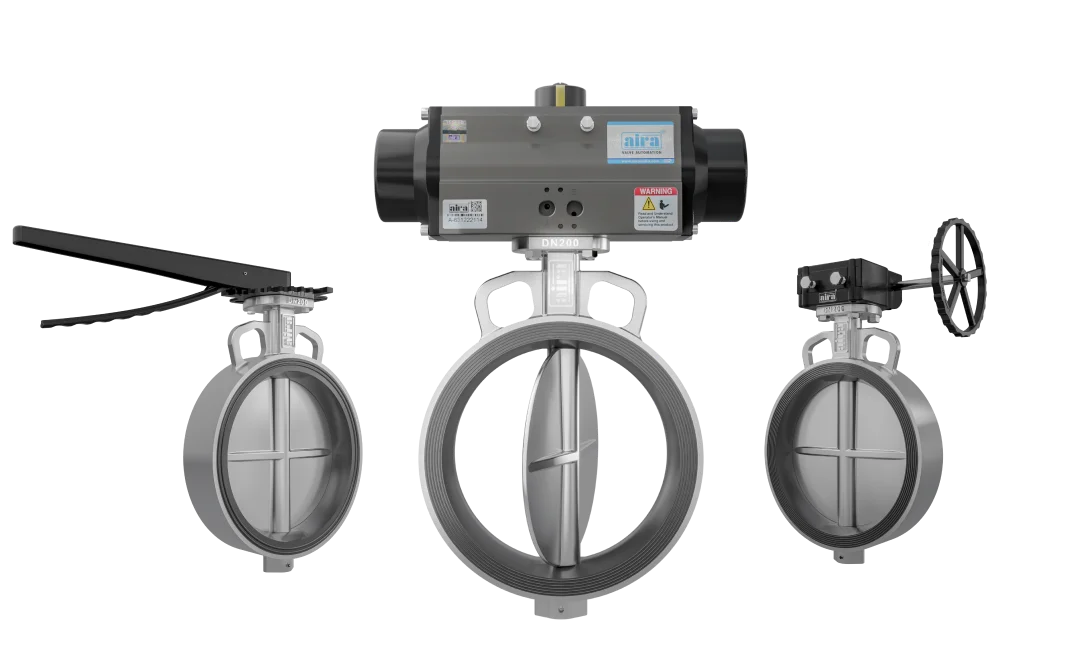

Aira Euro Automation Pvt. Ltd Well Known for their Wafer type Butterfly Valve Manufacturer and Exporter.

We Serve Pneumatic Actuator Wafer Type Butterfly Valve in many Countries like Malaysia, Tanzania, Africa, Oman, Egypt, and many more.

We have a wide range of Pneumatic Actuator Operated Wafer Type Butterfly Valve with Excellent Features like -20°C to 80°C Temperature and PN 10 / PN 16 Pressure Rating also provide PN 20 as per customer request.

Our Pneumatic Actuator Wafer Type Butterfly Valve also know only Wafer type Butterfly Valve in Valve Market.

Specification & Standard

Size Range

1.1/2" To 60" (40MM To 1500MM)

Tempreature Range

-20°C To 80°C For Nitrile Seat (Depending On MOC)

Pressurre Class

PN 10 / PN 16 (PN 20 On Request)

Body Style

Wafer Type

Flange Drilling

IS 6392 / EN 1092 - 1 / EN 1092 - 2 / ASME B 16.5 150#

Body Materials

S.G.I / C.I / D.I / WCB / CF8 / CF8M / CF3M / SS 304L / DUPLEX / HAST ALLOY / MONEL

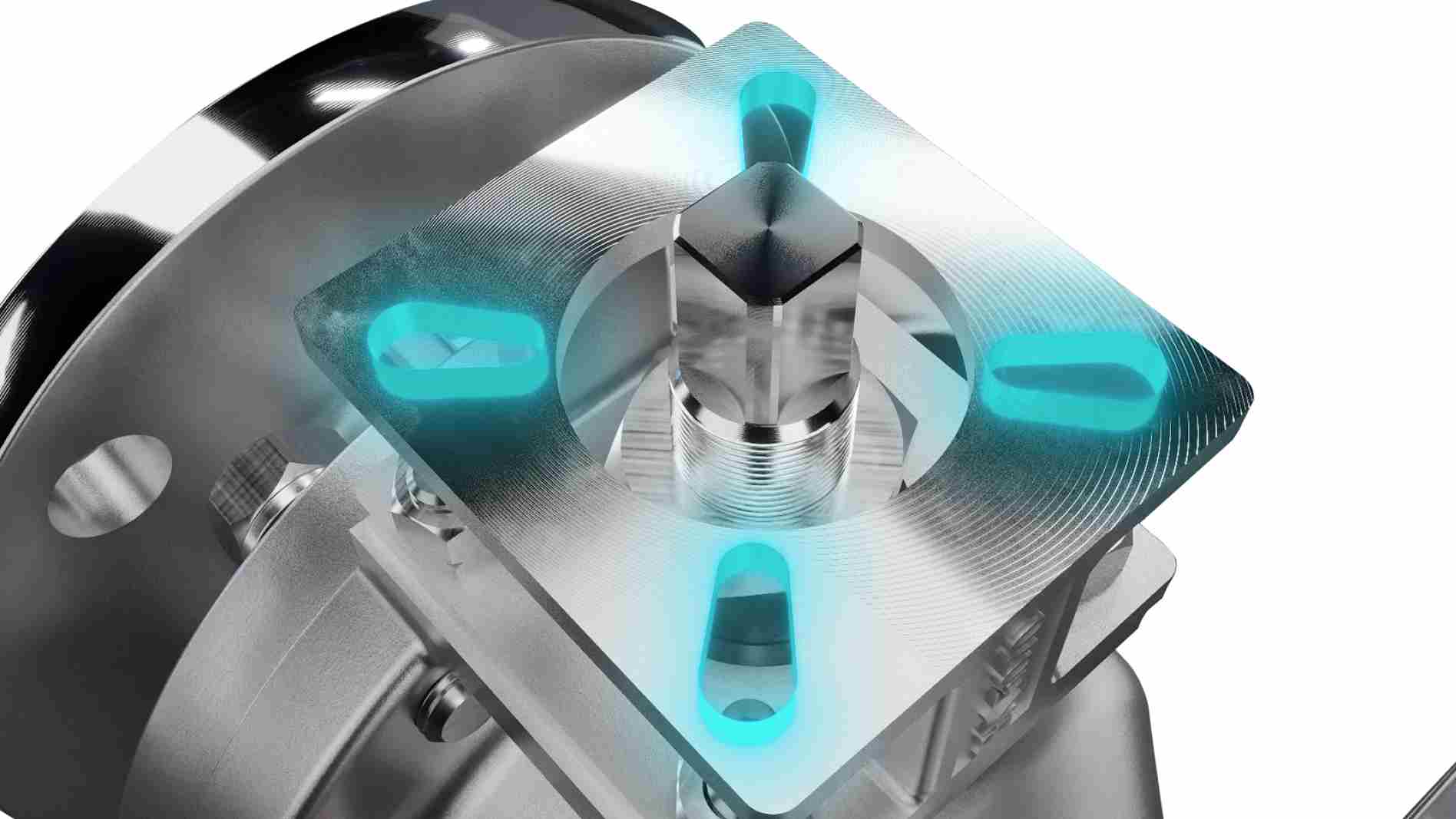

Stem Materials

SS 304 / 316 / 410 / 17 - 4 PH / Super Duplex 2507 / 2205

Seat Materials

NBR / EPDM PTFE / MODIFIED PTFE / RPTFE / CFT / GFT / DEVLON / PEEK / NYLON / AIRA-250

Disc Materials

S.G.I / CF8 / CF8M / CF3M / WCB + ENP / HAST ALLOY / DUPLEX / MONEL / ASTM A - 995

Seat Leakage Class

Tight Shut Off

Flange Standard Conformity

ASME B16.5 / 16.47 Series A Class 150

Top Flange Drilling

ISO 5211

Design And Manufacturer

API 609 Category A / IS:13095 / BS EN 593

Valve Face To Face Dimension

Short Wafer As Per ISO 5752 TAB 5/API 609 Category A ISO 5752 TAB 1 / BS EN-593 / BS EN-558

Inspection & Testing

API 598 / BS EN 12266 -1

End Connection

Wafer type Suit 150#, Table'D', Table'E' & IS 6392 Table 11 ( PN 10 / PN 16 )

Certification

Design CE Approved, SIL3 Approved, POD Approved

1 – Robust Construction: Made with durable materials and a rubber lining to enhance corrosion resistance and longevity.

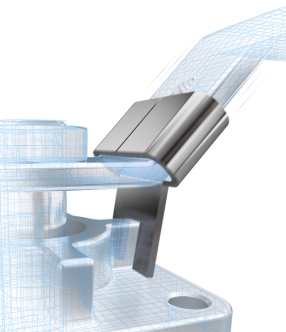

2 – Efficient Flow Control: Designed for precise regulation of flow, minimizing pressure drops and turbulence.

3 – Compact Design: The wafer-type configuration allows for easy installation between flanges, saving space and reducing weight.

4 – Excellent Sealing Performance: The rubber lining ensures a tight seal, preventing leakage and enhancing operational reliability.

5 – Low Maintenance: Engineered for reliability, requiring minimal maintenance and ensuring long-term performance.

6 – Easy Operation: Manual or actuated options available for user-friendly operation in different settings.

7 – Temperature and Pressure Tolerance: Designed to withstand a range of temperatures and pressures, making it adaptable to various conditions.

8 – Standardized Flange Compatibility: Compatible with standard flange sizes, facilitating seamless integration into existing systems.

9 – Cost-Effective Solution: Offers an economical choice for effective flow management without compromising quality.

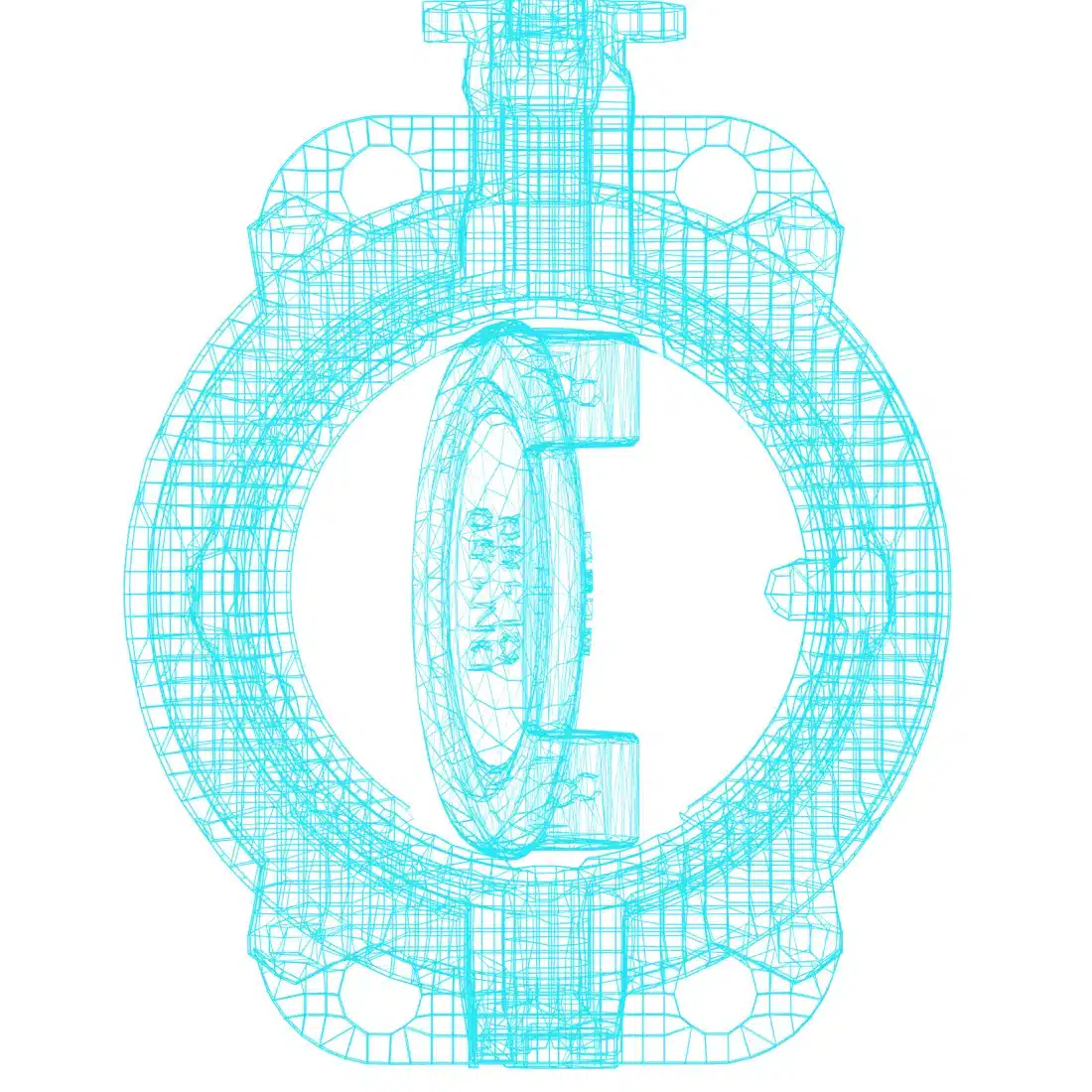

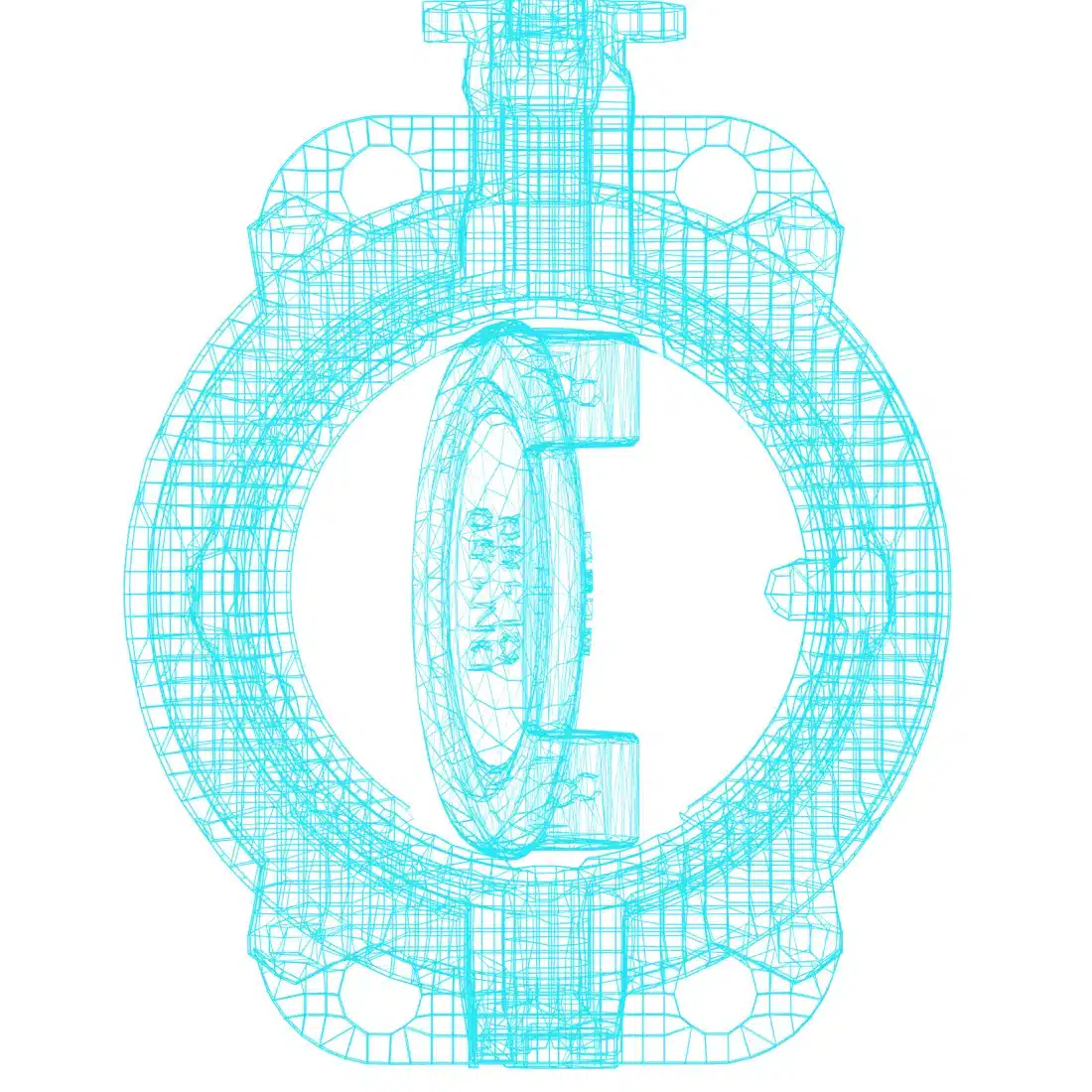

Rubber Lined

Wafer Type Butterfly Valve

Rubber Lined

Wafer Type Butterfly Valve

Dimension Table

ADDONS

Related Products

Working Days: Monday to Saturday.Tell Us How We Can Help You

Request A Quote

Complete control over products allows us to ensure our customers receive the best quality prices and service