Approvals

Aira Euro Automation offers stainless steel 304 rotary actuators for corrosive environments. The rack and pinion transmitted rotary actuator is available in single-acting and double acting actuation. It is designed as per international standard ISO 5211 for easy and quick mounting. With 90° rotation, this actuator can produce torque up to 1069 NM. To operate this actuator, the normal air supply pressure is required from 4Kg/cm² to maximum 8Kg/cm².

Specification & Standard

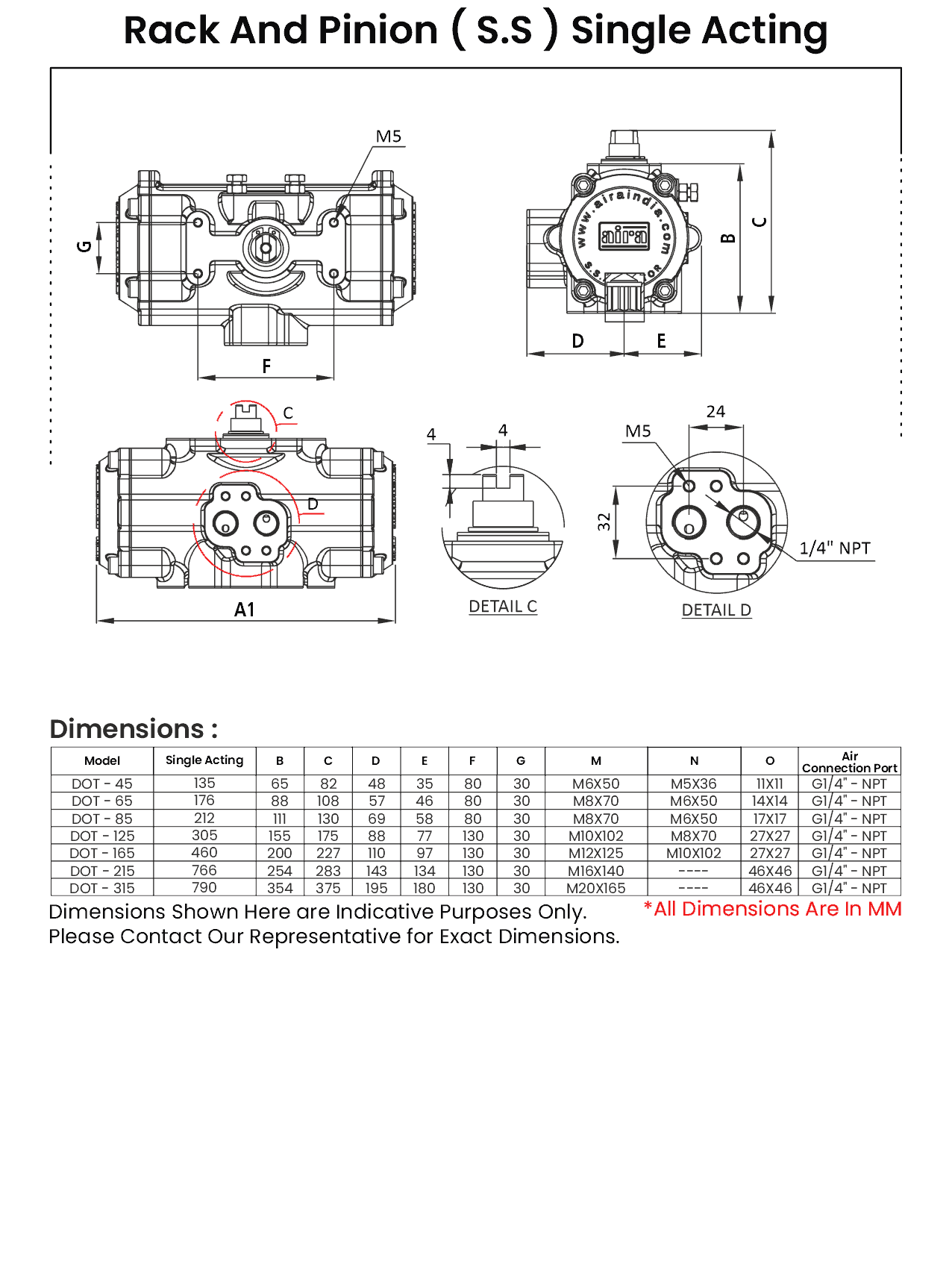

Size Range

Dot-45 To DOT-315

Temperature Range

Upto 150°C

Working Pressure

4 To 8 Bar

Method Of Transmission

Rack And Pinion Type

Actuation

Double Acting/ Single Acting

Body

IC CF8/ CF8M

Caps And Rack

IC CF8/ CF8M

Pinion

S.S.304/ S.S.316

Seals

Buna - N/ Viton

Air Pressure

Normal Air Supply Pressure: 4KG/ CM², Air Supply Pressure: 8KG/CM² Max

Actuator Design

ISO 5211 (Actuator Can Be Quickly And Easily Mounting)

Rotation

90° – Quarter Turn

Torque

0 To 1461 - NM

Mounting PCD

ISO 5211

Body Material

S.S - 304/ S.S - 316

Piston Material

304/ 316

Application

Operating For Valve

1 – Excellent corrosion resistance.

All main parts of actuator and it’s accessories are made from stainless steel. The body and end-caps is made by investment casting stainless steel. The CF8 (304) and CF8M (316) are available for choice. The pinion and fastening are made by 304 or 316 on requiring.Nearly 20 years experience of application proved that this kind of stainless steel pneumatic is able to offer excellent resistance to most corrosive chemicals (such as acid, alkali) as well as corrosive industry atmospheres, such as offshore, oil and gas platform, pharmaceutical and food industry.

2 – Wide scope of output torque.

Totally, we have 6 different size (specifications) actuators for choice. The output torque range is from 15Nm to 3815Nm at 5 Bar. The stainless steel actuator with 3815Nm is biggest one in the World now.

3 – Smooth and long life operation.

High level manufacturing technology for the rack & pinion in our workshop allows this actuator not only to cycle more than 500,000 times free from failure but also to offer exceptionally smooth actuation due to the low friction generated during rotral operations.

4 – Flexible adjustment in travel ends

The two independent external travel stop bolts allow ±5°adjustment at 0°and 90° of the quarter travel.

We use only high grade quality materials in making our products. We use IC CF8 or CF8M casting material for actuator bodies and caps & racks. For pinions, we use AISI S.S. 304 or S.S. 316 and the seals are available in Buna-N and Viton. We tested each actuator before delivery to ensure the quality of the product.

The ATEX, SIL-3, and CE-certified rotary actuator required dry or lubricated compressed air to operate. It requires 2~8 Bar air supply pressure for double acting and spring return. The standard operating temperature -20°C to 80°C with NBR ‘O’ ring and for high temperature Viton ‘O’ ring, it can sustain -15°C to 150°C temperature. For low temperature -35°C to 80°C is also available with a Silicon ‘O’ ring.

It is recommended that periodic checks be performed to make sure that all fasteners remain tight.

The actuator is supplied ready-lubricated. No further lubrication is required.

On spring return actuators, spring fatigue may set in requiring the replacement of the spring. Spring should always be replaced in full sets.

Under certain working conditions like Heavy Duty, non-compatible operating media, or abnormal operating conditions, internal seals should be checked periodically and replaced when necessary.

Advantages of Stainless Steel Pneumatic Actuator

The most important advantage of stainless steel actuators is that they can be placed in a corrosive atmosphere. It has the highest levels of corrosion protection. In comparison with others, stainless steel pneumatic actuators have a long life cycle. Best suitable for outdoor media and the seashore area. As we have a fully in-house inventory, and we use quality raw materials, hence we are the best pneumatic actuator manufacturer for high performance.

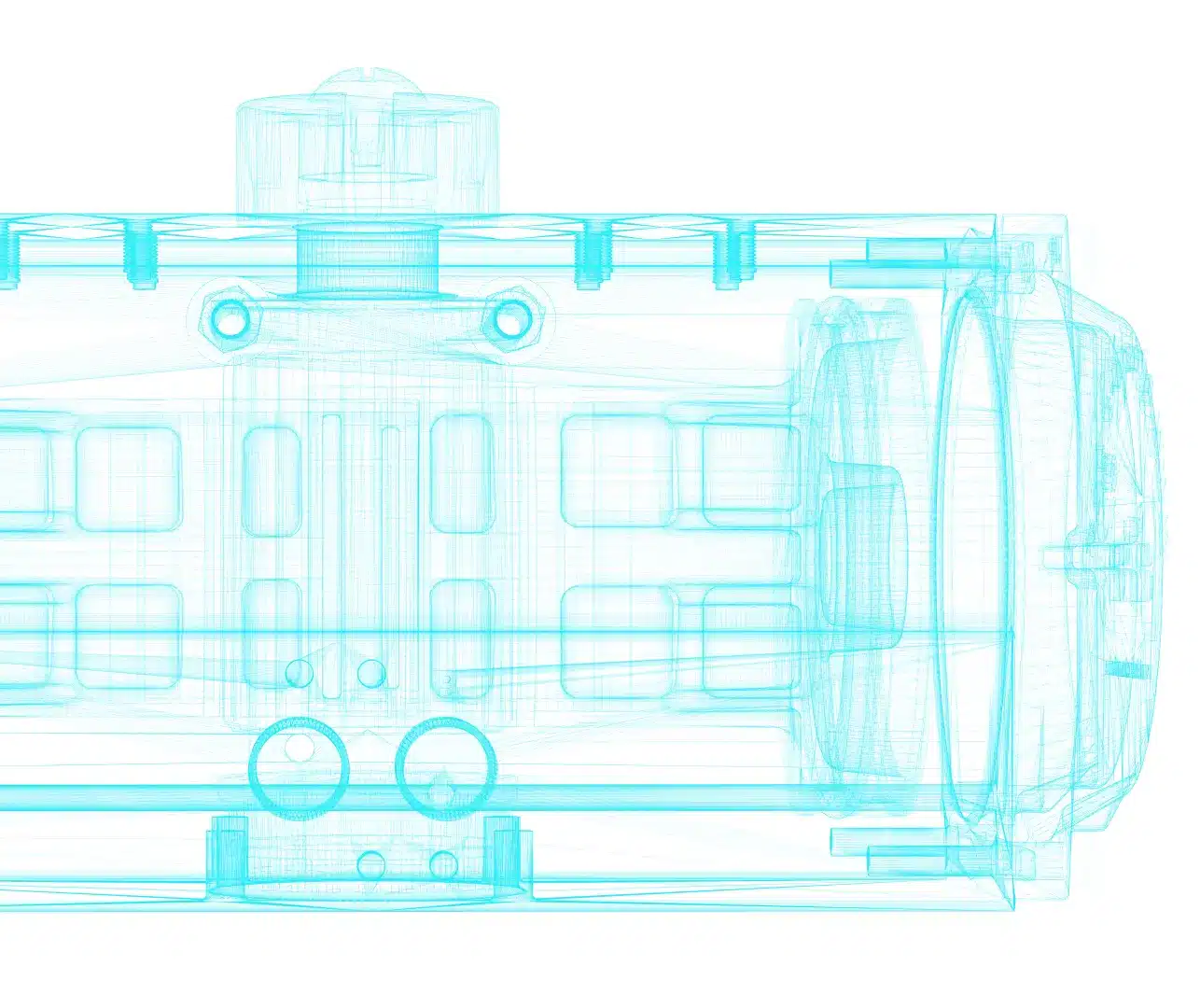

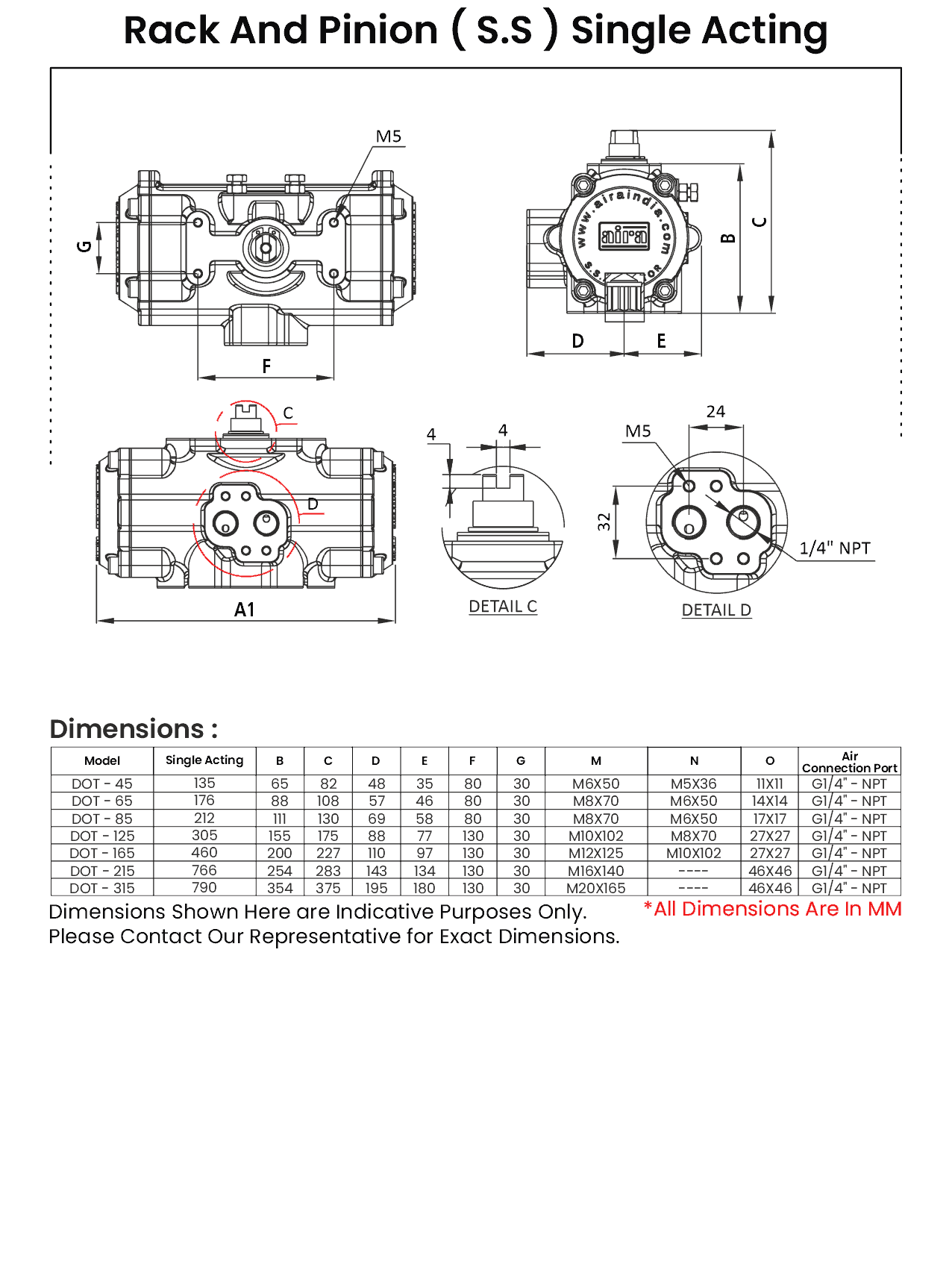

Rack And Pinion Stainless Steel

Single Acting Pneumatic Actuator

Rack And Pinion Stainless Steel

Single Acting Pneumatic Actuator

Dimension Table

Related Products

Working Days: Monday to Saturday.Tell Us How We Can Help You

Request A Quote

Complete control over products allows us to ensure our customers receive the best quality prices and service