Approvals

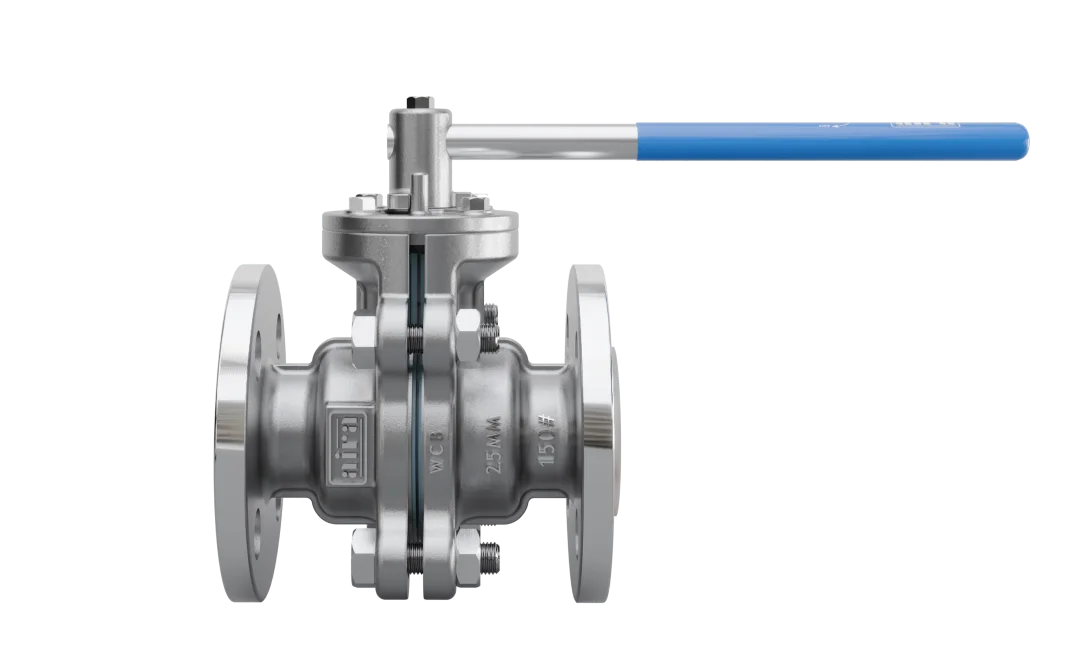

The aira Lined Ball valve is ideally suited for highly corrosive or abrasive application, where superior performance, tight shut – off and constant torque at almost no maintenance are required. Thanks to its wide range of optional linings it is suitable to handle a multitude of corrosive applications across a large variety of industries like chemical fine – chemical, pharmaceutical, petro – chemical , pulp & paper and mining. The aira lined ball valves has proven its superior performance as on/ off , control or throttle device for fluids in liquid or gas form.

Specification & Standard

Design & Manufacturer

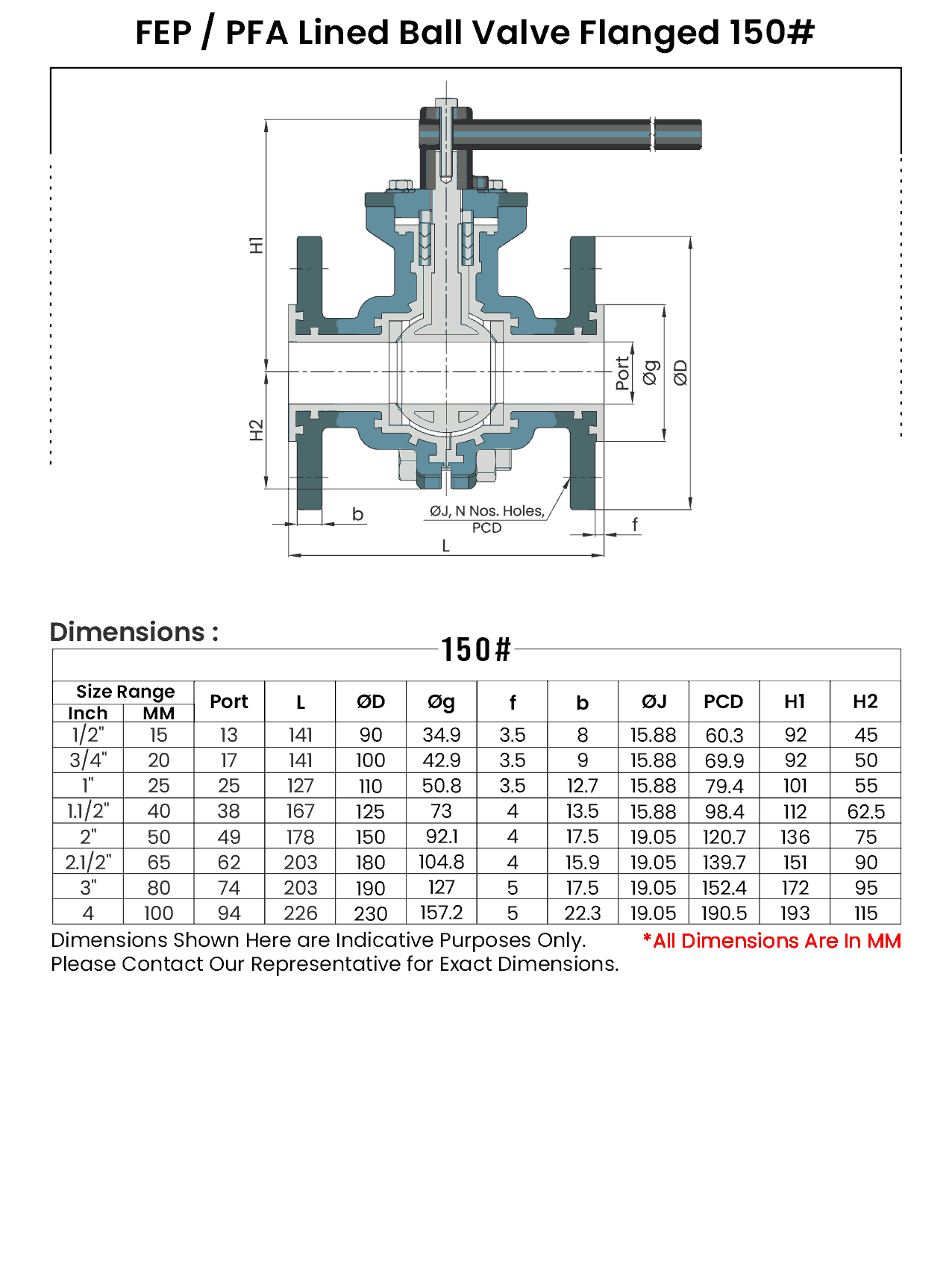

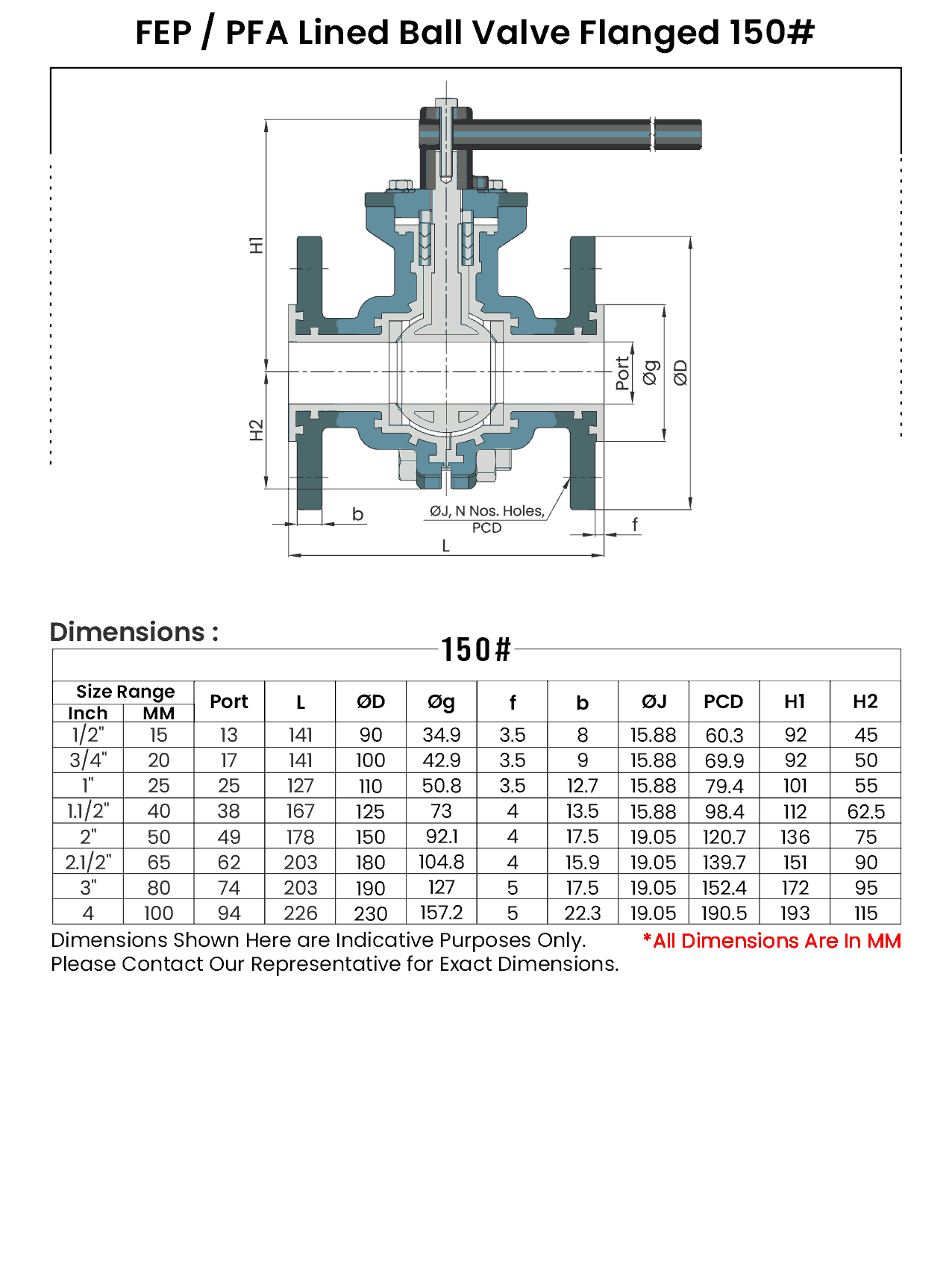

ASME B 16.34/ BS EN ISO 17292

Valve Face To Face Dimension

AS Per ASME B 16.10

Inspection & Testing

BS EN 12266 - 1/ ISO - 5208

Leakage Class

Class VI AS Per ISO - 5208

End Connection

Flanged 150#/ 300#

Valve Rating

Flangend 150#

Spark Test

15 Kv DC to 40 Kv DC

Size Range

1/2'' To 4'' (15MM To 100MM)

Temperature Range

-50' C To 300' For Soft Seated Valves. Contact Works For Special Requirement

Pressure Class

PN 6/10

Media

Chemical

Body Type

Flanged 150#

Body Material

CAST IRON(CI), DUCTILE IRON(DI), S.G IRON(SGI), WCB, CF8, CF8M, CF3M, SS 304L, DUPLEX, HAST ALLOY, MONEL

Ball Material

CF8, CF8M, WCB, HAST ALLOY, DUPLEX, MONEL, CF3M

Seat Material

PTFE, RPTFE, CFT, GFT, MODIFIED PTFE, AIRA-250

Flange Drilling

ASME B 16.5 CLASS 150#

Certification

Design CE Approved, SIL3 Approved, IBR Approved

Shout Off Rating

VI Class

Fugitive Emissions

Yes

Stem Material

CF8, CF8M, WCB + ENP, HAST ALLOY, DUPLEX, MONEL, CF3M

Disc Material

CF8, CF8M, WCB + ENP, HAST ALLOY, DUPLEX, MONEL, CF3M

1 – “aira” Make corrosion resistant Virgin Fluoropolymer lined Valves. aira’s lined valves provide bubble – tight shutoff, low maintenance, no leak & integrated ball & stem assembly.

2 – For, Performance, Safety & Reliability.

3 – Two piece design with 3MM to 6MM lining on all wetted parts with, VIRGIN FEP/ PFA. Inspected Upto 20,000 V DC fore checking Defects FEP Upto 160°C & PFA Upto 200°C.

4 – Lining securely gripped into the body by DOVE tail.

5 – Range of different body & ball material also available.

PFA-FEP

Lined Ball Valve

PFA-FEP

Lined Ball Valve

Dimension Table

ADDONS

Related Products

Working Days: Monday to Saturday.Tell Us How We Can Help You

Request A Quote

Complete control over products allows us to ensure our customers receive the best quality prices and service