Since 1990, we have built a strong reputation for delivering high-quality, reliable valves tailored for demanding applications across multiple sectors.

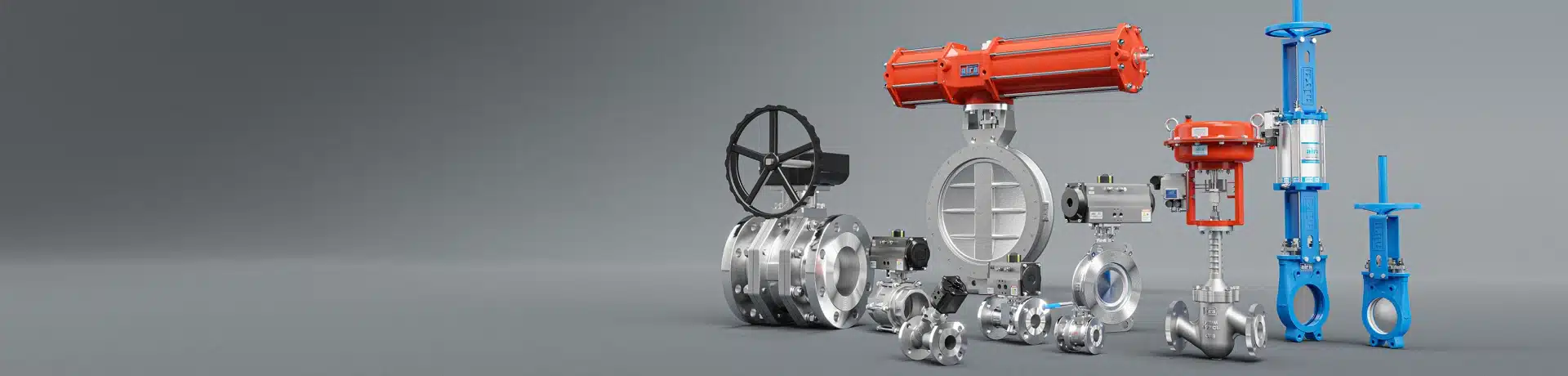

Our comprehensive product range serves diverse industries, including oil & gas, mining, cement, water treatment, and chemical processing, establishing us as a preferred Knife Edge Gate Valve Supplier in India and beyond.

Types of Aira’s Knife Edge Gate Valves

Aira Euro Automation offers two specialized variants of knife edge gate valves, engineered for optimal performance in challenging industrial environments.

- Bi Directional Knife Edge Gate Valve

Available in sizes from 50mm to 300mm, this valve handles pressures from 5 to 10 bar and temperatures up to 200°C. Manufactured as per MSS SP-81 standards, it features body materials like CI, SGI, DI, and WCB, with disc options in SS 304/316/316L/310 or Duplex 2205. The seat materials (NBR/EPDM/Viton/PTFE) ensure tight sealing (Class VI leakage) for applications in mining, pulp & paper, cement, sugar, and fossil fuel power plants.

- Uni Directional Knife Edge Gate Valve

With a broader size range (50mm to 1200mm) and higher temperature resistance (up to 250°C), this valve operates from 0.5 to 10 bar pressure. Compliant with MSS SP-81 standards, it offers multiple body styles (single piece, semi lug, full lug, wafer) and materials (CI, WCB, CF8, CF8M, SS 316). Ideal for slurry handling, sugar processing, and material handling industries, it provides Class VI sealing with optional metal-to-metal seats for tougher applications.

How Aira’s Knife Edge Gate Valve Works?

The knife edge design features a sharp-edged disc that cuts through thick fluids, slurries, and viscous media, preventing clogging and ensuring smooth operation. When actuated, the blade creates a tight seal against the seat, minimizing leakage.

Key benefits include:

- Superior flow control for abrasive and high-solid-content media

- Minimal pressure drop due to full-bore design

- Durable construction resistant to wear and corrosion

- Easy maintenance with simple, robust components

Why Choose Aira for Knife Edge Gate Valve?

As a trusted Knife Edge Gate Valve Exporter, we stand out for:

- ✔ Proven Quality – Manufactured to international standards (MSS SP-81) with premium materials

✔ Cost-Effective Solutions – Competitive pricing without compromising durability

✔ Wide Industrial Suitability – Perfect for mining, cement, power plants, and chemical processing

✔ Customization Options – Multiple sizes, materials, and pressure ratings

✔ Reliable Performance – Long service life with minimal maintenance

Whether you need a Knife Edge Gate Valve Supplier for slurry handling or high-temperature applications, Aira Euro Automation delivers unmatched reliability. Contact us today for tailored solutions!

Looking for more industrial valves? Explore our butterfly valve category for more solutions.