Approvals

A lot of industries use and store liquid materials in huge quantities. When these industries discharge liquid containers, the flow of the liquid forceful enough to cause damage to the pipelines. In order to prevent these accidents, engineers install High Pressure Ball Valves which in turn helps in controlling the high liquid flow.

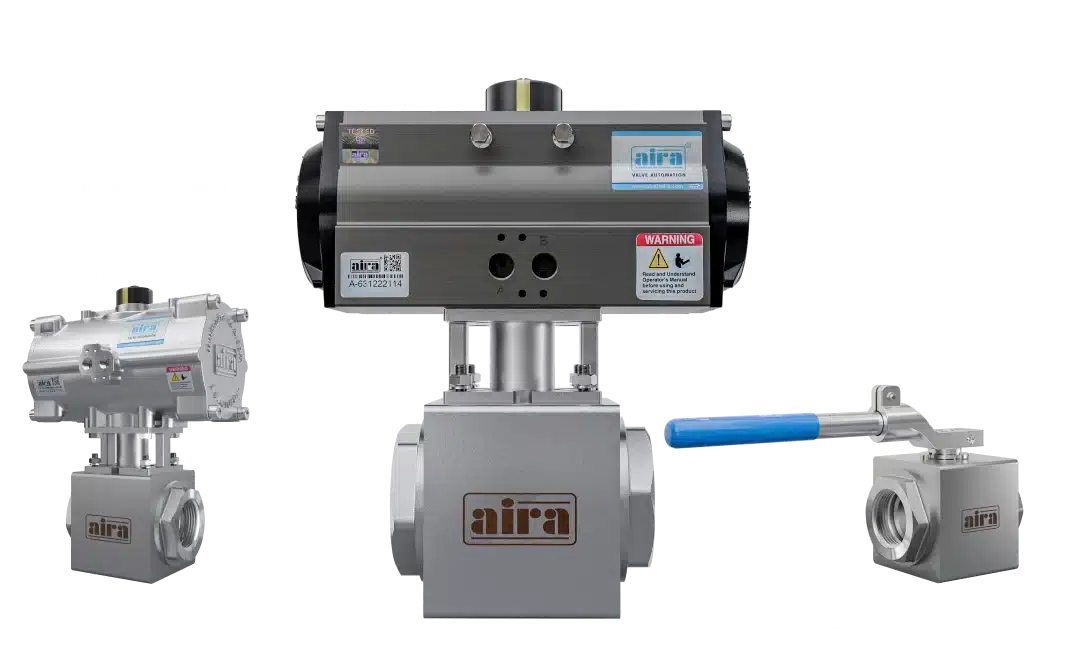

Being well aware of this condition, Aira Euro has designed a High Pressure Ball Valve that can sustain pressure up to 500 Bar.

How to use a High Pressure Ball valve?

Each valve is designed for a unique intent and has a dedicated position in the process line. High-Pressure Ball valves are designed to prevent damages from happening in the pipelines and hence they are installed in between the container and the starting point of the pipeline.

Where to use a High Pressure Ball valve?

High Pressure ball valves are generally used in places where the fluid outcome pressure is high such as in water distribution plants, water parks, chemical industries, etc. Their sectors are the ones that store fluid in huge quantities and use them as per their requirements.

The Best Quality High Pressure Ball Valve Manufacturers

Any ball valve that works under 3000 PSI pressure can be considered as a High Pressure Ball Valve. Its maximum capacity is 7500 i.e. 500 Bar. Aira Euro Automation manufactures these types of ball valves which are 1/4” to 1” in size and can easily work under -20°C to 150°C temperature.

High Pressure Ball Valve is a three-piece designed valve and it uses Forged Carbon / S.S 304 / S.S 316 casting material for its Body and S.S 316 for the ball.

Specification & Standard

Design & Manufacturer

ASME B 16.34 BS/ EN ISO 17292

Threader Fitting

ASME B 1.20

Inspection And Testing

API 598/ ISO-5208/ BS EN 12266-1

Leakage Class

Class VI ISO - 5208

Stem Material

AISI 410, SS 304 , Ss 316 , Ss 304l, SS 316l, DUPLEX 2205, DUPLEX 2507, MONEL

Seat Material

PTFE, RPTFE, CFT, GFT, MODIFIED PTFE, AIRA-250, NYLON, DEVLON, PEEK, D- PLASTIC

Certification

POD

Size Range

1/2" To 2” BSP/ NPT Thread

Tempreature Range

-50' C To 300' For Soft Seated Valves. Contact Works For Special Requierment. ( Upto -50°C To 420°C )

Pressurre Class

150#

Media

Air/ Water/ Oil/ Gas

Body Material

CAST IRON(CI), DUCTILE IRON(DI), S.G IRON(SGI), WCB, CF8, CF8M, CF3M, SS 304L, DUPLEX, HAST ALLOY, MONEL

Ball Material

CF8, CF8M, WCB + ENP, HAST ALLOY, DUPLEX, MONEL, CF3M

Ball Type

Solid

1- Fully Compliant To ASME B16.34 & API 608.

2- ISO 5211 Mounting Pad Bolt Pattern.

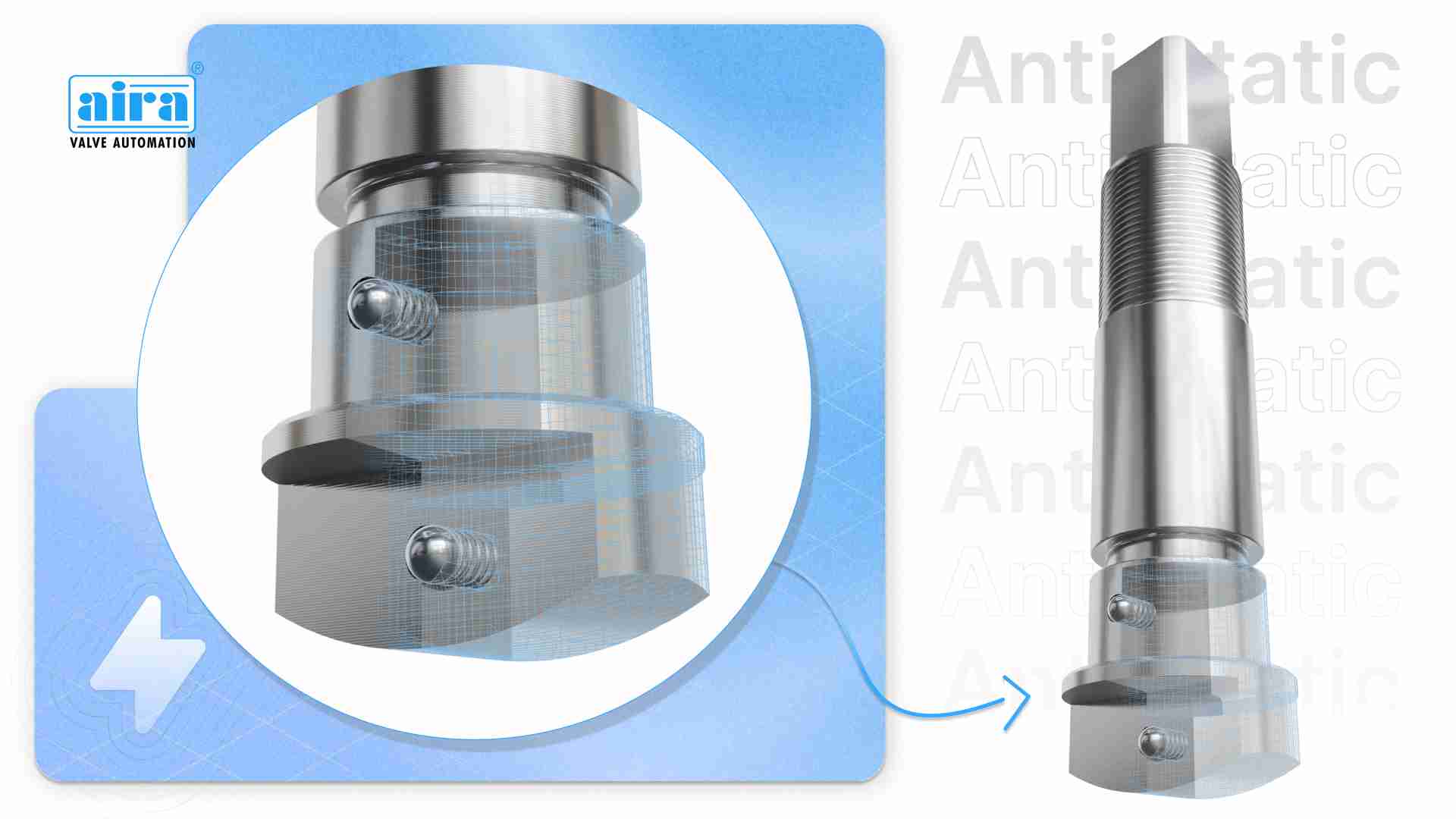

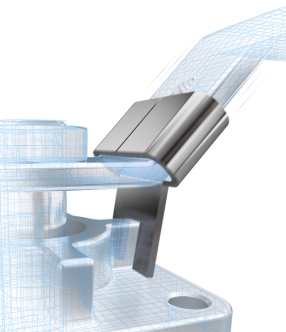

3- Blow Outproof Steam Design.

4- Anti Static Grounded Ball & Stem.

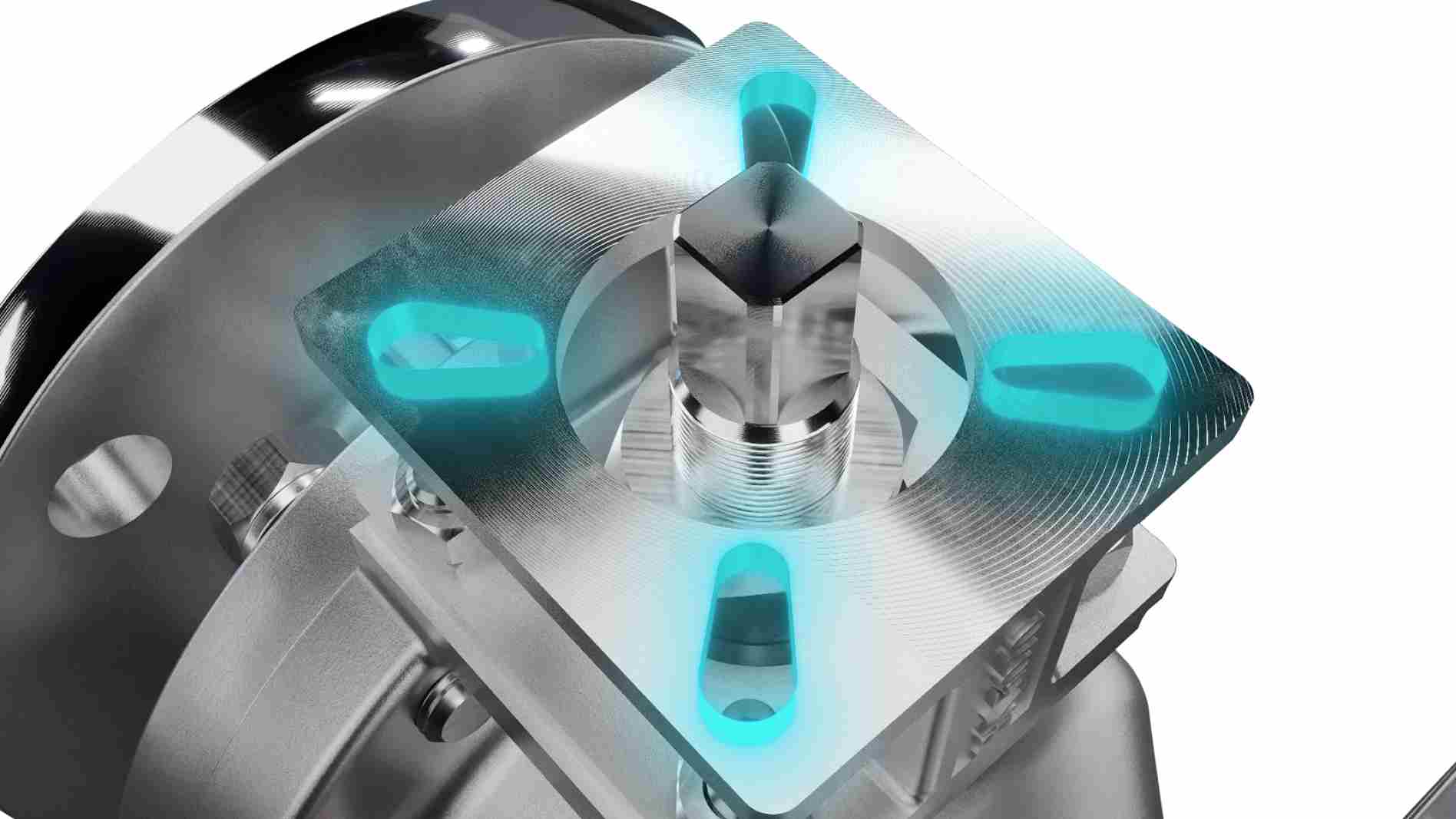

5- Slot Vented Ball For Thermal Expansion.

6- Also Manufacture In Special Grade MOC Like Supen Duplex, Hast Alloy Etc.

7- Ball Seal: RPTFE, TFM, PEEK.

High Pressure

4000 PSI Screwed End Ball Valve

High Pressure

4000 PSI Screwed End Ball Valve

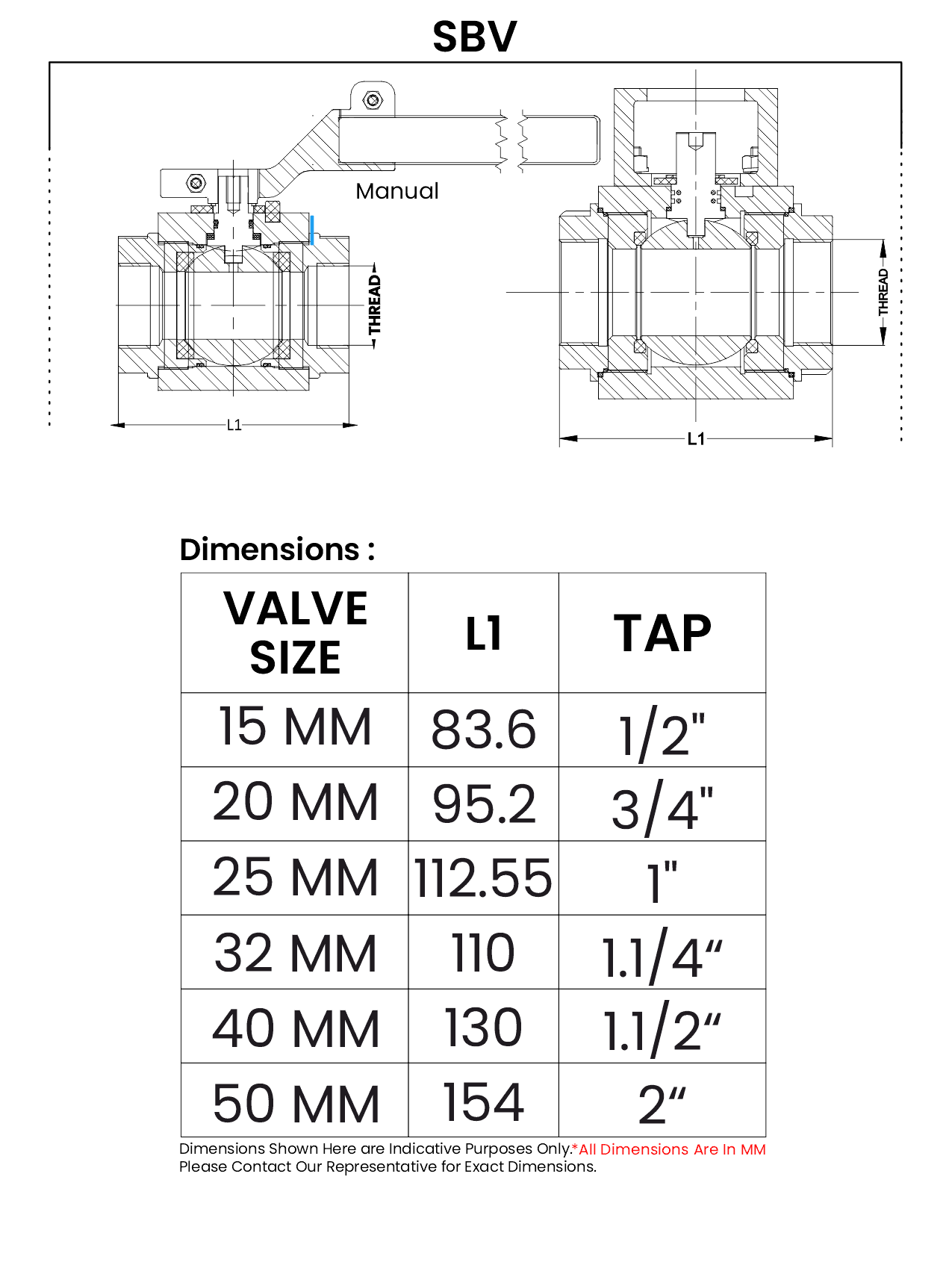

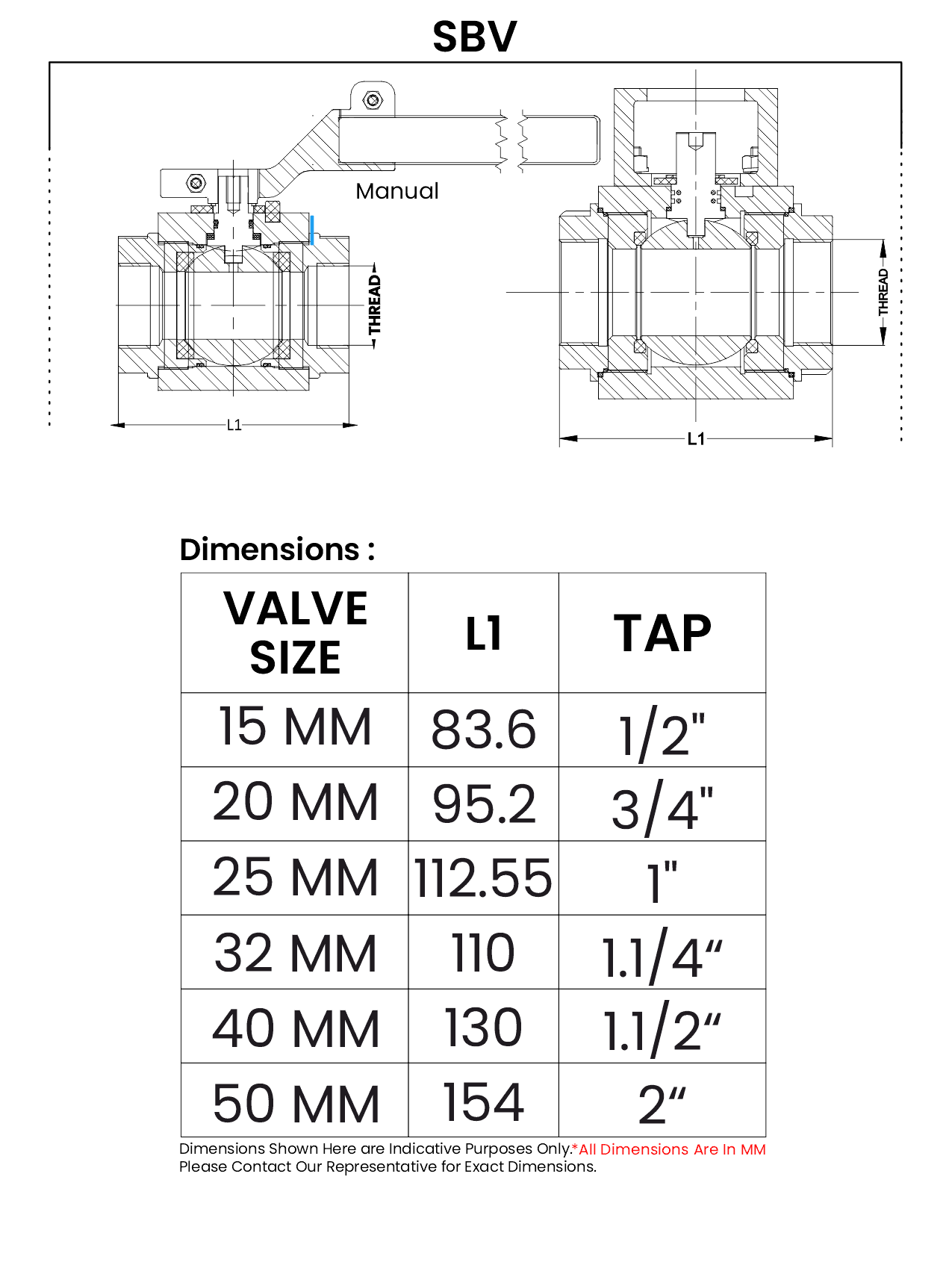

Dimension Table

ADDONS

Related Products

Working Days: Monday to Saturday.Tell Us How We Can Help You

Request A Quote

Complete control over products allows us to ensure our customers receive the best quality prices and service