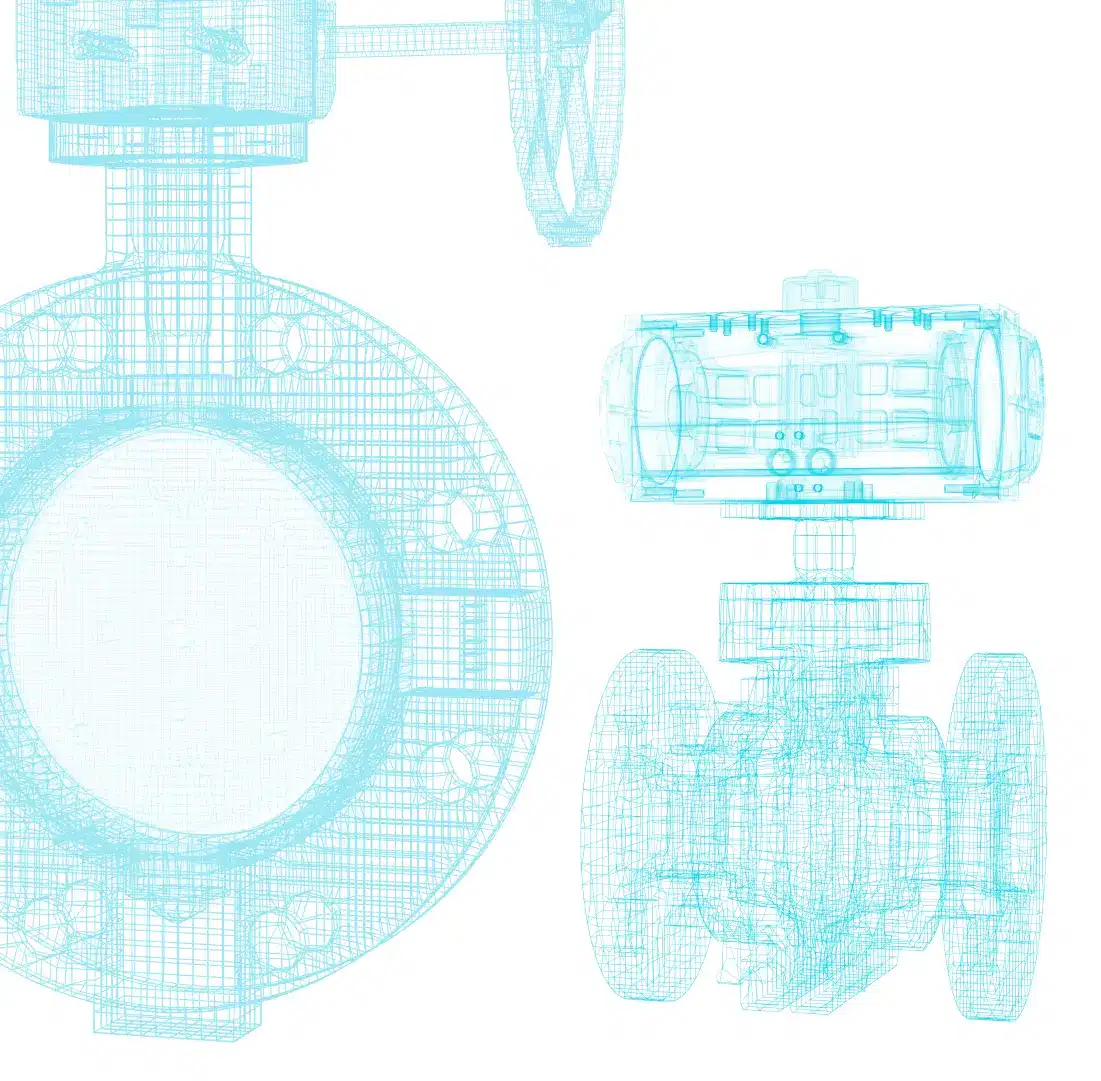

”aira” offers/PFA Lined Plug Valve Fully – lined, quarter turn non lubricated plug valve ideally suited for corrosive application. Locking of Liner to body and molding technique permit use on many chemical services with higher pressure and vacuums without fear of liner collapse, shrinkage, stress cracking and blowout. Excellent sealing capability.

Specification & Standard

Design & Manufacturer

BSEN ISO 17292, ASME B 16.34

Valve Face To Face Dimension

AS Per BS 16.10

Inspection & Testing

BS EN 12266 - 1/ISO - 5208

Leakage Class

Class VI AS Per ISO - 5208

End Connection

Flanged 150#/300#

Valve Rating

Flangend 150#

Spark Test

15 Kv DC to 40 Kv DC

Size Range

1/2'' To 8'' (15MM to 200MM)

Temperature Range

-50' C TO 300' For Soft Seated Valves. Contact Works For Special Requirement

Pressure Class

PN 6/10

Media

Chemical

Body Material

CAST IRON(CI), DUCTILE IRON(DI), S.G IRON(SGI), WCB, CF8, CF8M, CF3M, SS 304L, DUPLEX, HAST ALLOY, MONEL

Plug Material

CF8, CF8M, WCB + ENP, HAST ALLOY, DUPLEX, MONEL, CF3M

Design Standard

BSEN ISO 17292, ASME B 16.34

Flange Drilling

ASME B 16.5 Class 150#

Certification

Design CE Approved, SIL3 Approed, IBR Approved

Body Type

Flanged 150#, 300#

Fugitive Emissions

Yes

Shout Off Rating

VI Class

Stem Material

CF8, CF8M, WCB + ENP, HAST ALLOY, DUPLEX, MONEL, CF3M

Disc Material

CF8, CF8M, WCB + ENP, HAST ALLOY, DUPLEX, MONEL, CF3M

01 – LINED PLUG VALVES : ”aira” lined plug valves are made to with stand harsh corrosive and abrasive media with much higher sealing capacity than all other quarter turn valves to perform superiorly even after prolonged use. This makes it ideally suited as more economical choice in the long run. Made to

perform in vacuum as well as in high pressure application.

02 – CORROSION PROTECTION : Low porosity FEP/PFA (Perfluoroalkoxy) as standard liner. All cast parts have an epoxy based coating for added protection from corrosion attack due to permeation.

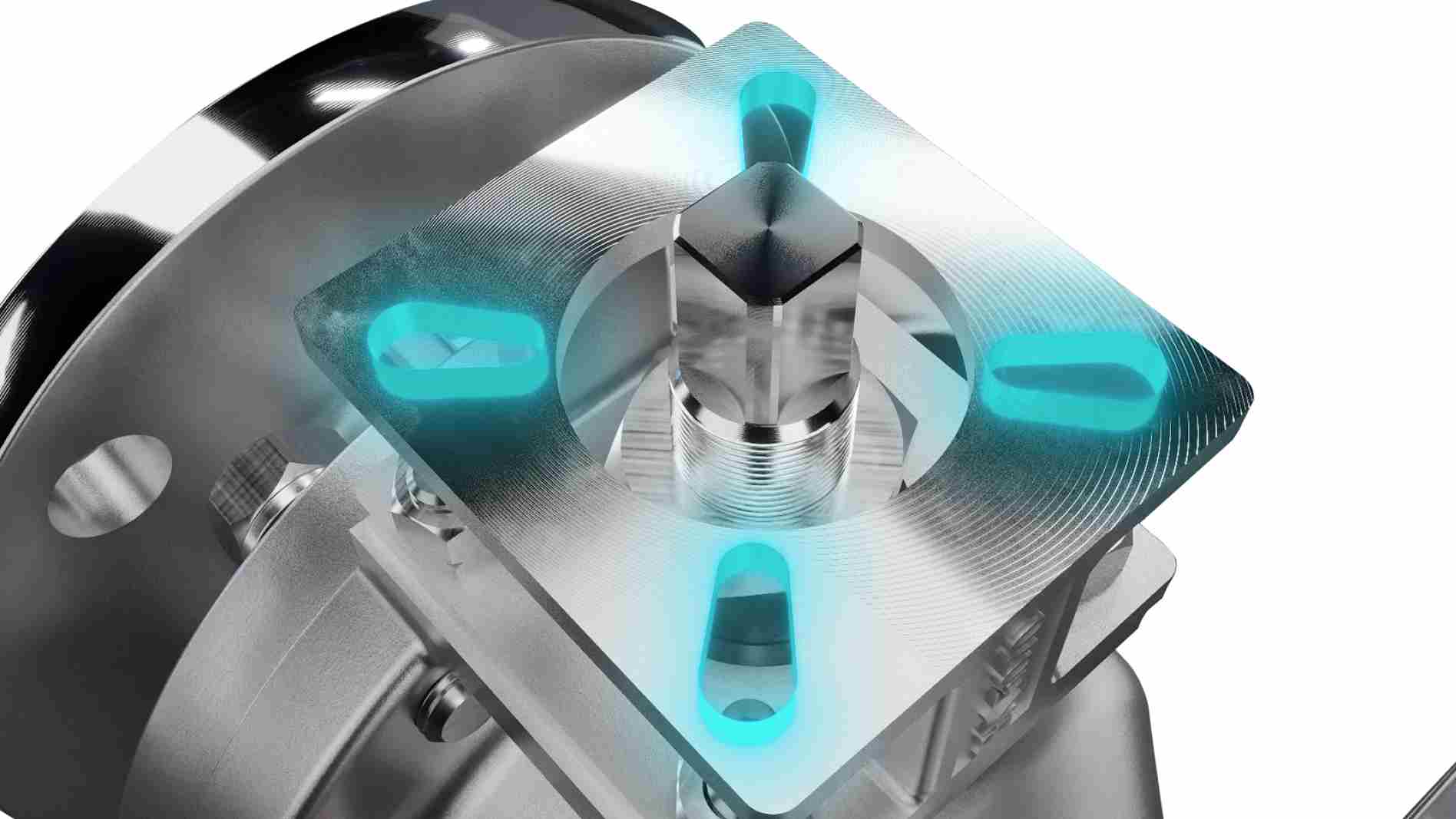

03 – LOCKED-IN LINER : ”aira” Lined plug valves feature an unpigmented virgin FEP/PFA lining applied by Transfer Moulding and locked into castings by machined dovetail-shaped recesses in body casting and cast holes. This resists shrinkage and blow out. The liner is spark tested in accordance with ASTM D5126 SPEC.

04 – CAVITY-FREE DESIGN : By design, Lined Plug Valve are cavity-free both in open and closed positions – No particle accumulation/-Ideal for corrosive slurry applications.

05 – UNMATCHED SUPERIOR SEALING. BI-DIRECTIONAL ZERO LEAKAGE : Primary sealing by PFA eith PFA 360°C contact with the lined body. Leaving absolutely no chance for In – line or atmospheric leakage. This gives highest level of sealing when compared to any other valve design. ( When compared with conventional ball valve, butterfly valve, gate valve, globe valve designs.)- Tight shut – off/Compression seal ( Upstream & downstream )/- Sealed at both plug & stem

FEP-PFA

Lined Flanged End Plug Valve

FEP-PFA

Lined Flanged End Plug Valve

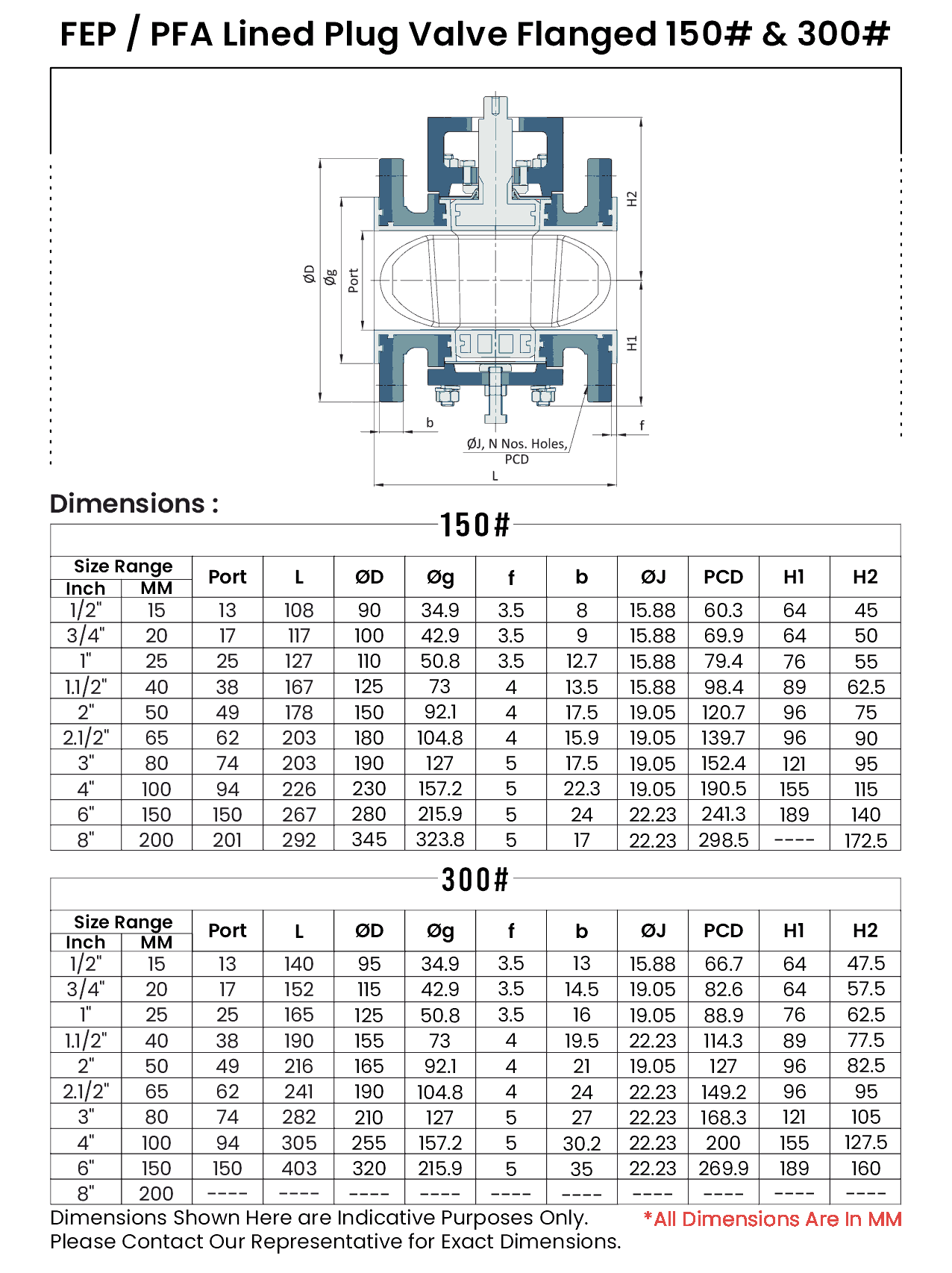

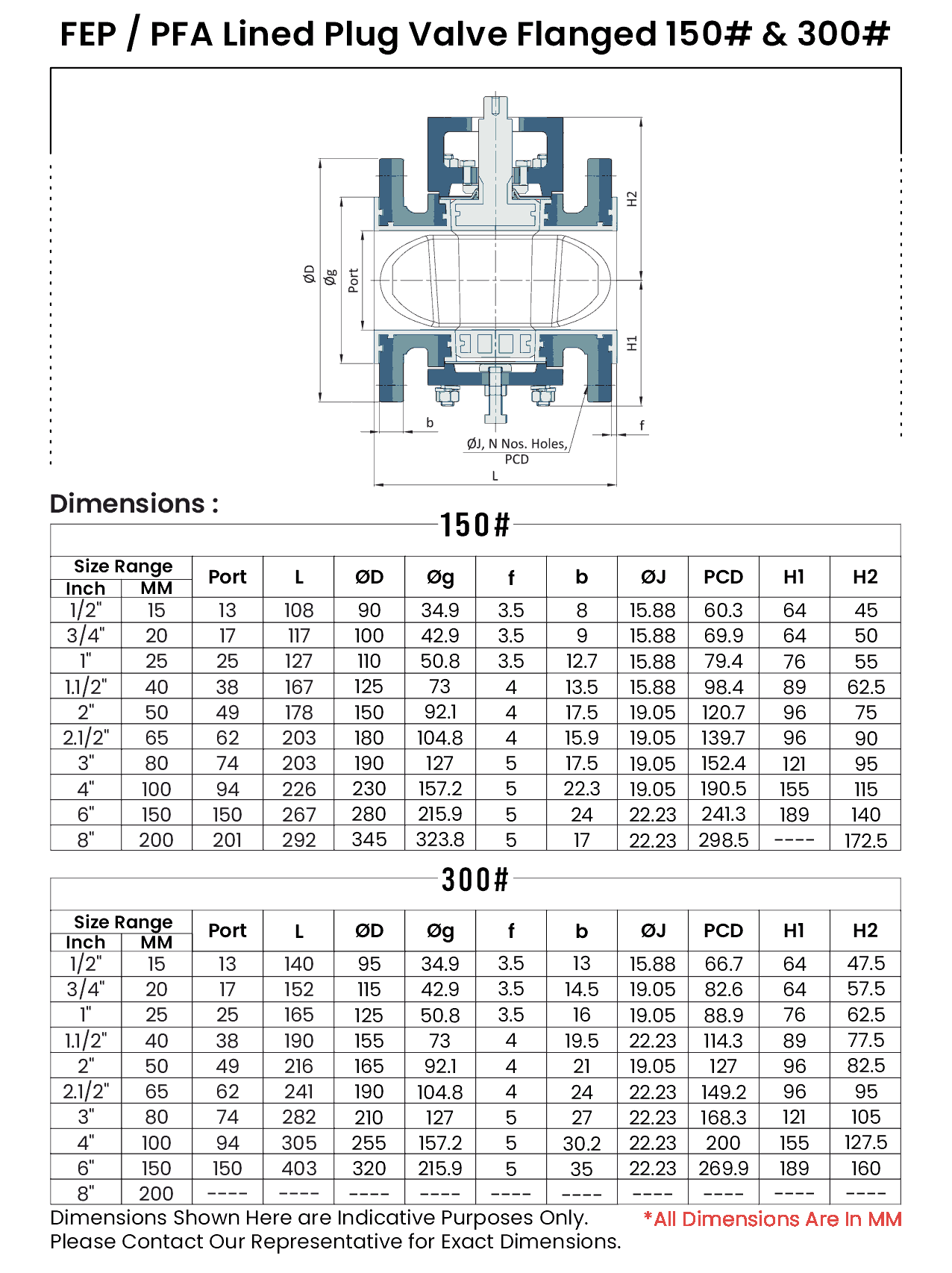

Dimension Table

ADDONS

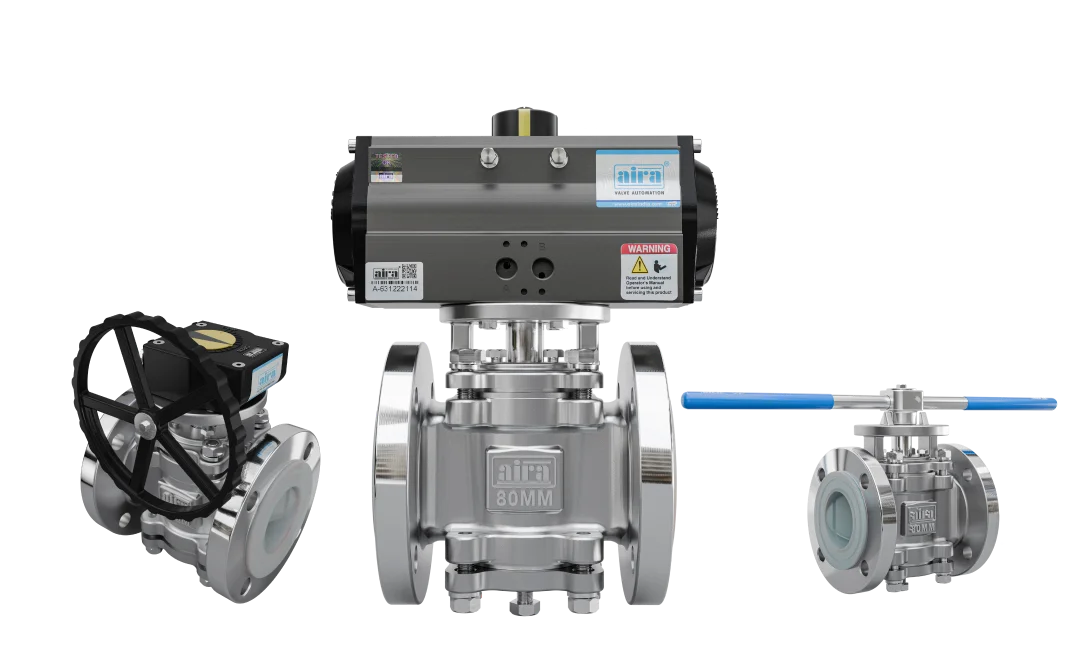

Related Products

Working Days: Monday to Saturday.Tell Us How We Can Help You

Request A Quote

Complete control over products allows us to ensure our customers receive the best quality prices and service