Approvals

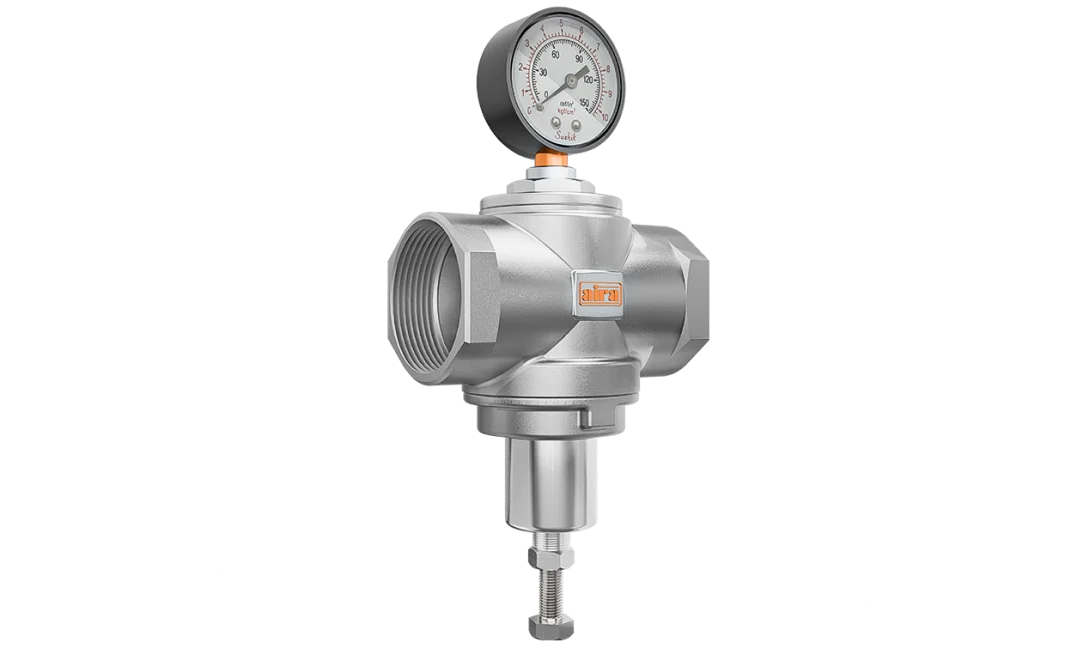

A Direct Activated Pressure Reducing Valve (PRV) is a type of valve used to automatically reduce and maintain a desired downstream pressure in a piping system. It operates without external power, relying instead on the pressure of the fluid passing through it.

In the screwed small version, the valve is designed for small pipelines and typically features a screwed connection for easy installation and maintenance. These valves are ideal for applications where precise pressure control is required, such as in water systems, heating systems, or gas pipelines.

Specification & Standard

Size Range

15MM To 100MM

Temperature Range

Upto 85°C

Max Inlet Pressure

Upto 18 kg/cm²

Pressure Adjusting Range

1 ~ 6 kg/cm² & 4 ~ 10 kg/cm²

Body Style

Globe Type

Body Materials

CF8 / CF8M

Piston Materials

CF8 / CF8M

Seat

NBR

Design Standard

Manufacture - Standard

Testing Standard

Manufacture - Standard

Face To Face

Manufacture - Standard

Applications

Water / Gas / Air & Oil

End Connection

Screwed End

1 – Direct Activation Mechanism: Provides precise and responsive pressure control with minimal lag.

2 – Adjustable Pressure Setting: Easily configurable to meet specific system requirements.

3 – Durable Construction: Made from high-quality materials for long-lasting performance and reliability.

4 – Compact Design: Space-saving and suitable for a variety of installation environments.

5 – Easy Installation: Simplifies setup with user-friendly connections and clear instructions.

6 – Stable Performance: Maintains consistent pressure despite fluctuations in input pressure or flow rates.

7 – Low Maintenance: Designed for minimal upkeep, reducing operational costs over time.

8 – Versatile Applications: Suitable for various industries including water, oil, and gas systems.

Direct Activated

Pressure Reducing Valve Screwed

Direct Activated

Pressure Reducing Valve Screwed

Dimension Table

Related Products

Working Days: Monday to Saturday.Tell Us How We Can Help You

Request A Quote

Complete control over products allows us to ensure our customers receive the best quality prices and service