Ball Valves are the most common equipment to control fluid pipelines. Even though there are other valves to control fluids, ball valves are more prominent given to their specific design, leakage controls, and quick on-off application. As we know, the basic design is of a hollow sphere globe fixed in the seat and a quarter turn movement inside the ball allows/prevents the fluid to pass through.

Sometimes problems occur when these valves require maintenance. For that engineers have designed various types of Ball Valves such as Single Piece Design, Two Piece Design and Three Piece design and all of these have their unique specialties and purpose.

To get a brief about them read the following section below:

Single Piece Design Ball Valve

Single piece design Ball Valve is the most leading design and is known for its zero leakage. This valve is directly fixed between the fluid pipeline joints by flanged ends which makes the chances of fluid leakage tend to zero. Due to this specialty, this valve is highly used for gas applications. It is a low-cost valve which is why most call it a “throwaway” after use kind of valve.

Two Piece Design Ball Valve

As the name defines, the body of this valve is made in two pieces; one has an integral flange and the other acts as a connector that is bolted together in the pipeline. This is the most common valve in the industry as it has just one body joint which in turn minimizes the chances of leakage. It is also an easy maintenance valve.

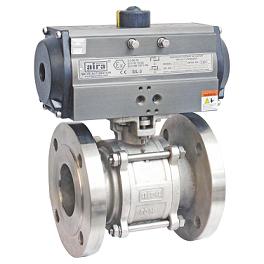

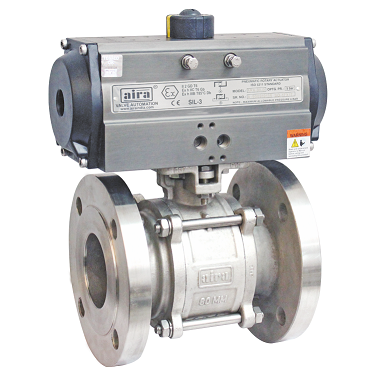

Three Piece Design Ball Valve

A three-piece design ball valve has one body part and two connectors which are bolted together. Three-piece design is ideal for inland maintenance. This valve is not required to be brought down for maintenance. It can simply be rectified by removing the three boards and swings like a fulcrum and any internal changes to the ball, seat, body seals, etc can be done. That being said, this valve has a higher leakage problem as compared to a two-piece design ball valve.

End Connections of Ball Valve

End connections play an important role in the valve industry as they define how a valve is fitted in between the pipelines. There are many end connections available like a Spigot end connection. Socket end connection, Capillary end connection, Compression end connection, Socket Weld end connection, Butt Weld end connection, Screwed end connection and Flanged end connection.

The highly used end connections are the Screwed Ended, the Flanged end and the Weld end connections. The Flange end connection is very popular amongst these. They are easy to install and remove with minimum leaks. They are bolted to the mating pipe flange. To confirm tight seals, engineers always put a gasket between the machine facings of the flanges.

Aira Euro Automation is a prominent Ball Valve Manufacturer in India. They have a huge range of ball valves such as high pressure ball valve, 2 piece ball valve, 3 piece ball valve and etc.