Hello Readers, Do you know there are several valves that are specifically designed and developed to control gas and oil applications? Yes, there are more than 5 types of industrial control valves that are developed for use in the gas and oil industry. Ball Valve, Butterfly Valve, Gate Valve, Globe Valve, Plug Valve, and safety valve are on this list. In order to maintain the flow of oil and gas in pipelines, several reliable pieces of equipment are required. Control valves are one of those pieces of equipment. It is impossible for the oil and gas industry to ensure that crude oil, refined gas, natural gas, and other materials reach their destination without control valves. In this article, we will recognize the role of ball valves in the petroleum industry. So first of all let’s take a brief look at the ball valve.

What is a Ball Valve?

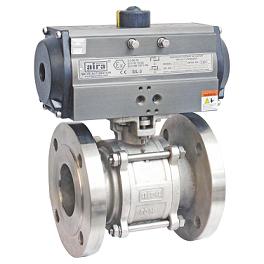

As well as on/off, ball valves can also be used for throttling purposes. They are easy to open and close, requiring only a quarter-turn. There is a hollow ball inside the valve body, which is connected to the stem. You need to rotate the stem to operate the ball valve. When the hollow ball is parallel to the pipeline it allows the fluid to flow out and vice-versa when the hollow ball is perpendicular. Ball Valve requires a manual hand lever or actuator in large sizes and at high operating pressures to overcome the operating torque. Both onshore and offshore oil and gas production facilities use ball valves to shut off fluid. Ball valves are also used in furnace fuel gas systems.

What type of Ball Valves are There?

As per their body structure and design, the ball valves can be classified into three types: single-piece ball valve, two-piece design ball valve, and three-piece design ball valve. According to the ball valve’s central hollow ball fittings, the ball valves are also available in three types which are: side entry ball valve, floating ball valve, and trunnion mounted ball valve. These all types of ball valves are designed for a specific functionality apart from controlling the fluid flow. As ball valves are lightweight and perform quick action in comparison to other valves, these are the most demanded valves in chemical industries as well. Due to this engineers have also designed lined ball valves to control corrosive fluids. The PFA and PTFA materials are used in lined ball valves. There are also fire-safe design ball valves, extended shaft ball valves, and UPVC ball valves available. Multiple-way ball valves are also available in the market.

Is a Ball Valve Better than a Gate Valve?

A ball valve and a gate valve are two of the most commonly used valves in plumbing or gas systems to control the flow of fluid. In terms of sealing effectiveness and reliability and longevity, ball valves are more reliable than gate valves but tend to be more expensive. These valves are often used for shutoffs and controls. Water hammer is more likely to occur with ball valves since they can open and close immediately. If a valve is closed quickly on water flowing at high pressure through pipes, it can create shock waves in the plumbing that cause it to hammer. Water hammer can weaken and break a pipe if the pressure is high enough. Because of this, users are advised to turn the ball valve lever slowly to avoid water hammers.

What are the Advantages of Ball Valve?

Ball Valves are a perfect choice for controlling different applications and sometimes they are picked over any other valves which have less control in the throttling use. Some advantages of ball valves are as below:

- Ball Valves offer leak-proof services,

- They can be opened and closed quickly,

- Multiple-way ball valves like 3 way and 4 way Ball Valves are used for diverting and mixing applications.

- They can be installed vertically or horizontally

- Ball Valves are much smaller than gate valves,

- Ball Valves are lighter than gate valves,

- Neither Gate valves nor Globe valves offer multi-designed flexibility like ball valves, thereby reducing the number of valves required.

- Ball valves are manufactured in different sizes and shapes providing flexibility in the selection

- High-quality ball valves provide safe operation at high temperatures and pressures, and

- Ball valves require less force to operate when compared with other valves.

When would you use a Ball Valve?

Ball Valves are one of the most efficient valves due to their multi-versions. You have to calculate the upstream pressure as well as the fluid’s maximum temperature before choosing any industrial valve. Ball Valves come with various end connections so you can easily assemble them into your pipeline. For high-pressure applications, high-pressure ball valves are also available on the market. If you are going to control corrosive chemicals, then lined ball valves are the ideal option for you. In comparison to other industrial valves, ball valves are a little costly. So you have to choose wisely. If you don’t have much of an idea about the valves you can contact a ball valve manufacturer in Yemen like Aira Euro Automation. Their engineers will help you in the selection of suitable valves for your application.

Conclusion

Ball Valves are one of the most common and very beneficial industrial valves. As the ball valve comes with multiple designs and multiple end connections, which makes them superior valves. The fire-safe ball valves are ideal to control inflammable media.