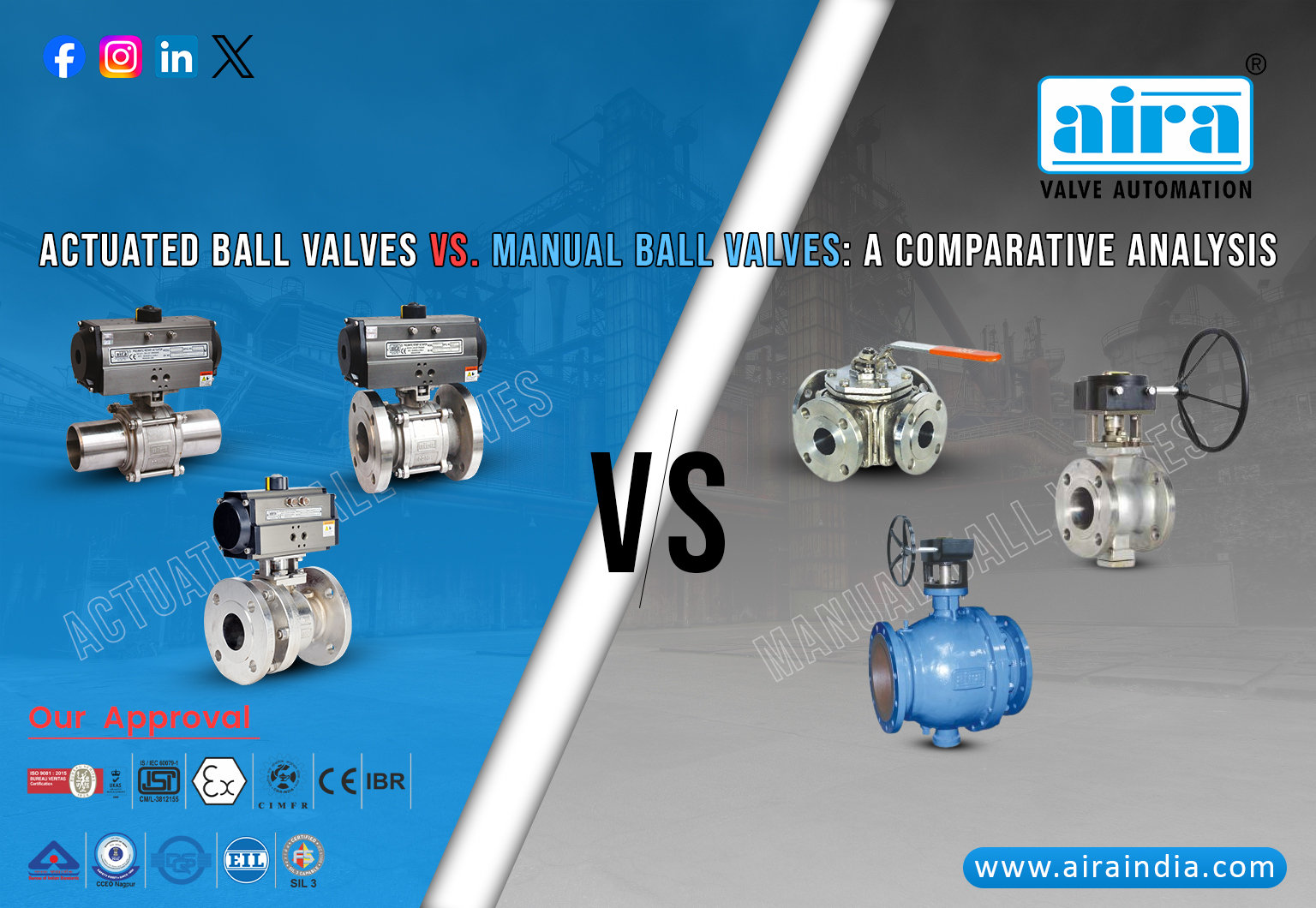

When it is about controlling the flow of liquids and gases in commercial strategies, ball valves are a popular preference because of their reliability and performance. However, the selection between actuated and manual ball valves can drastically impact your gadget’s overall performance.

This article explores an intensive evaluation of those two forms of valves, that specialize in their running thoughts, benefits, and differences. These records are particularly useful for engineers, procurement specialists, and preservation employees in industries including oil and gasoline, metal production, and manufacturing.

Understanding Ball Valves

Ball valves are quarter-turn valves that use a hole, perforated, and pivoting ball to manipulate drift through them. They are recognized for their durability, capability to address immoderate strain and temperature, and high-quality shut-off abilities. The primary difference in ball valves comes from how they may be operated: manually or through an actuator.

Manual Ball Valves: Working Principle and Advantages

Working Principle

Manual ball valves are operated by using way of a lever or handwheel that controls the rotation of the ball inside the valve. When the lever is turned 90 ranges, the ball rotates to both permit waft (open) or block flow (closed). The simplicity of this mechanism makes guide ball valves easy to carry out and maintain.

Advantages

Cost-Effective: Manual ball valves are commonly less high-priced than their actuated opposite numbers, making them a price-effective answer for plenty of applications.

Simplicity: With fewer additives, guide ball valves are easy to function and preserve. This simplicity additionally technique fewer points of functionality failure.

Reliability: Due to their trustworthy layout, guide ball valves are particularly dependable and lots less vulnerable to malfunctions.

Versatility: They are suitable for a sizable variety of packages, inclusive of residential plumbing, small industrial approaches, and systems wherein automation isn’t required.

Actuated Ball Valves: Working Principle and Types

Actuated ball valves, then again, use an outdoor energy delivery to automate the operation of the valve. This automation may be carried out through numerous types of actuators, inclusive of electric-powered powered and pneumatic actuators.

Electrically Actuated Ball Valves: Working Principle and Advantages

Working Principle

Electrically actuated ball valves use an electric-powered powered motor to rotate the ball inside the valve. The motor is controlled through the manner of an electrical signal, which lets in particular manage the valve’s function. This sort of actuator is right for programs requiring ways flung management and automation.

Advantages

Precision and Control: Electrically actuated ball valves offer particular manipulation over the go together with the waft, making them appropriate for programs that require correct glide law.

Remote Operation: These valves can be operated remotely, lowering the want for guide intervention and bearing in mind integration with automatic management systems.

Energy Efficiency: Electric actuators eat energy first-class whilst adjusting the valve, making them greater electricity-green as compared to special kinds of actuators.

Safety: In hazardous environments, faraway operation minimizes the risk to personnel.

Pneumatically Actuated Ball Valves: Working Principle and Advantages

Working Principle

Pneumatically actuated ball valves use compressed air to move a piston or diaphragm, which in turn rotates the ball within the valve. These actuators are known for their speedy response times and are frequently applied in applications where tempo is essential.

Advantages

Speed: Pneumatically actuated ball valves can open and near masses faster than electrically actuated valves, making them pleasant for packages requiring speedy reaction.

Durability: These valves are extraordinarily durable and may function reliably in harsh environments, collectively with those with high temperatures and corrosive materials.

Safety: Pneumatic actuators no longer produce sparks, making them appropriate to be used in explosive or flammable environments.

Power: They can generate an immoderate torque output, letting them feature big valves without problems.

Comparing Actuated and Manual Ball Valves:

Control and Automation

One of the maximum widespread variations among actuated and guide ball valves is the quantity of control and automation they provide. Actuated ball valves, whether electric or pneumatic, can be integrated into automated control systems, taking into account specific and far-flung operations. This automation enhances process management and may improve performance and safety in enterprise programs.

Manual ball valves, while much less complex, require bodily intervention to characteristic. This impediment makes them much less appropriate for programs in which no unusual adjustments or remote controls are necessary.

Cost and Maintenance

In phrases of fee, manual ball valves are commonly cheaper both in preliminary purchase and protection. They have fewer components and no longer require an out-of-door strength delivery, which could simplify installation and decrease expenses.

Actuated ball valves, while extra luxurious, offer lengthy-time period financial savings through improved device overall performance and reduced manual labor. Maintenance for actuated valves may be more complex because of the extra additives, but improvements in the actuator era have made them more and more dependable and less complex to the carrier.

Application Suitability

The desire for actuated and manual ball valves in large part depends on the unique necessities of the software:

Manual Ball Valves: Ideal for clean, low-hazard applications in which charge is a number one undertaking, and automation isn’t always crucial. Examples consist of residential plumbing, small-scale commercial strategies, and structures with uncommon modifications.

Electrically Actuated Ball Valves: Best ideal for programs requiring specific waft manipulation, a ways off operation, and integration with automated structures. Common in industries together with water remedy, HVAC, and any procedure manipulation applications.

Pneumatically Actuated Ball Valves: Perfect for programs wanting fast reaction times, excessive sturdiness, and operation in hazardous environments. These valves are normally used within the oil and gas organization, chemical processing, and any utility in which pace and reliability are critical.

Make the Right Choice

Choosing between actuated ball valves and manual ball valves involves thinking about several elements, consisting of the quantity of automation required, price constraints, and the appropriate wishes of the software. Manual ball valves provide simplicity, reliability, and fee effectiveness, making them appropriate for sincere programs. In comparison, actuated ball valves, whether or not electrically or pneumatically operated, provide advanced control, automation, and adaptability, making them essential in complicated business environments.

For agencies and engineers searching to optimize their systems, information on the differences and blessings of every kind of valve is crucial. At Aira Euro Automation, we provide a giant range of manual and actuated ball valves to satisfy various business needs. Our professional team is here to help you pick out the most pleasant valve way to enhance your operational performance and reliability.

By carefully comparing your particular necessities and leveraging the strengths of every sort of valve, you may ensure sure ultimate usual performance and longevity of your industrial procedures. Whether you need the simplicity and reliability of manual ball valves or the superior management and automation of actuated ball valves, Aira Euro Automation has the data and merchandise to fulfill your wishes.