A ball valve is a type of valve used for controlling the flow of gases and liquids. They allow fluid to flow through them in one direction only. They come in many shapes and sizes. This blog will focus on the ball valve. It opens and shuts by rotating a spherical ball with a handle. They are available in various sizes and types and can be used in places such as a chemical plant, a water treatment plant, a power plant, a gas station, a brewery, a swimming pool, a hot tub, a spa, a water or fuel pipeline. This blog will take a closer look at the ball valve.

- Ball Valves are used Worldwide in Fluid Power Systems as Control Valves

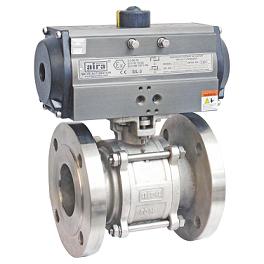

Ball valves are used worldwide in plumbing and fluid power systems as control valves. The valves are used to regulate the flow of air, water, oil, fuel, and other fluids. They are used in plumbing systems, air compressors, oil pumps, and HVAC systems. The ball valve is a one-way valve that uses a rotating ball to control flow. The ball can be moved to one of two positions by the handle. The valve is opened by rotating the ball to the left or right. It is closed by rotating it back to the center. The valves are made from brass, chrome, stainless steel, or plastic. They are used as a control valve for a single function.

- Different types of Ball Valves have Different Uses

Ball valves are the most common valves in plumbing. They are used in almost all homes. The ball valve is a simple device that allows the flow of fluid in one direction only. It contains a valve body, which is a hollow cylinder with a hole in the middle. The hole is called the ball seat. The ball is a round piece of metal with a hole in the middle. The ball valve is used to control the flow of liquid or gas. The ball is moved up and down to open or close the hole. The valve is either fully open or fully closed. Ball valves are also used in industrial settings. They are used in many different applications.

- How to Choose a Ball Valve

Ball valves are a type of quarter-turn valve used to regulate flow in a pipeline. The ball is housed in a spherical body and is moved between two seats by a mechanism operated by a handle. There are two main types of ball valves: swing-check valves and plug valves. The swing check valve is used for on-off service while the plug valve is used for throttling service. Ball valves are used in horizontal, vertical, and inverted pipelines on water, air, and other liquid systems.

- How to Choose the Best Ball Valve for Your Project

Ball Valves are commonly used in the plumbing industry. Ball valves allow for a reduction in pressure and flow of liquids and gases by means of a quarter-turn valve. Nearly every gas and liquid line will have a ball valve included in the system. When a flow of gas or liquid is needed, a ball valve is typically used. Ball valves are typically used for the following purposes: * To allow a system to be shut off completely * To allow a system to be controlled from a remote area * To allow a system to be controlled from a specific location * To shut off a leak

- How to Maintain a Ball Valve?

A ball valve is an important part of the pipeline system. It works by allowing the flow of product through the pipeline but preventing backflow. However, there is no need to worry about how to maintain ball valves because they are built to last. A ball valve is the simplest type of valve, which is why it is used in many applications. It consists of a valve that is mounted on a valve seat, which is the area of the pipeline where the valve is installed. The valve has a ball that rotates on the seat, allowing the flow of product to pass through the pipeline.