Approvals

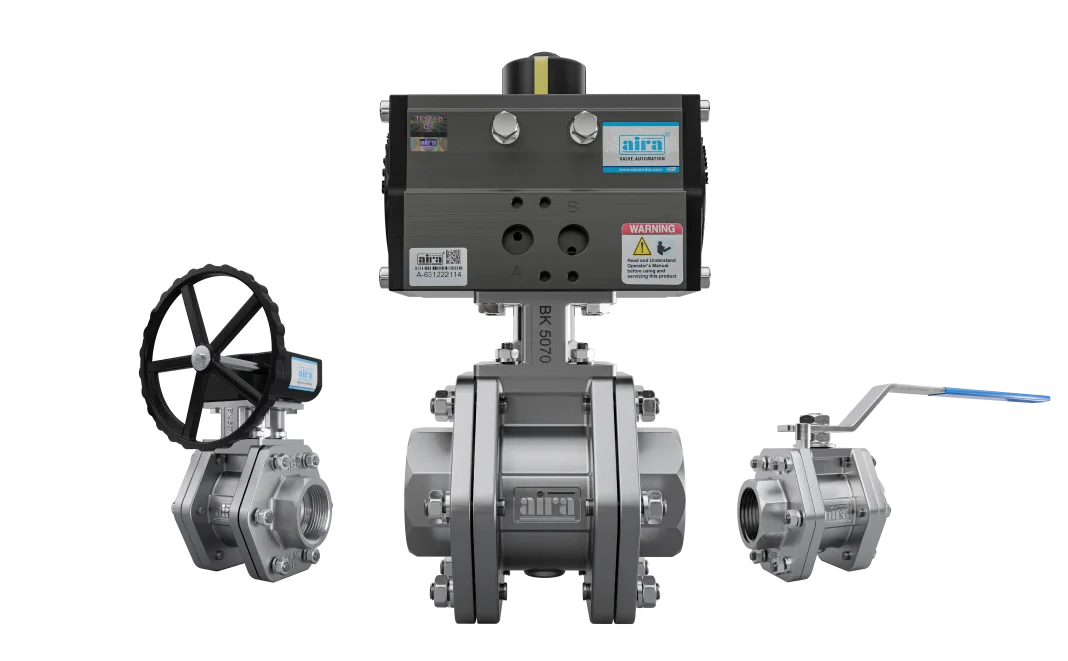

“aira” Offers Automation And Manually Operated Metal Seated Floating Ball Valve Designed For Using In The Several Conditions Such As High Temperature & High Friction Fluids Of Oil & Gas, Petroleum, Petrochemical, Chemical Power Generation, Pulp & Paper, Mining Industry.

Specification & Standard

Design & Manufacturer

ASME B 16.34/ BS EN ISO 17292

Valve Face To Face Dimension

ASME B 16.10

Inspection & Testing

API 598/ ISO-5208/ BS EN 12266-1

Leakage Class

ANSI FCI 70-2 Class IV - V

End Connection

ISO 7-1 FOR screwed BSPT/ ASME B 1.20.1 for Screwed BPT/ ASME B 16.5 for Flanged 150#

Size Range

1/2" To 4" Screw End

Tempreature Range

Upto -50°C To 550°C

Pressurre Class

150#

Media

Air/ Steam/ Oil & Gas

Leakage Class

Class Iv To V, Vi

Body Material

CAST IRON(CI), DUCTILE IRON(DI), S.G IRON(SGI), WCB, CF8, CF8M, CF3M, SS 304L, DUPLEX, HAST ALLOY, MONEL

Ball Material

CF8, CF8M, WCB + ENP, HAST ALLOY, DUPLEX, MONEL, CF3M

Ball Type

Hollow & Solid

Stem Material

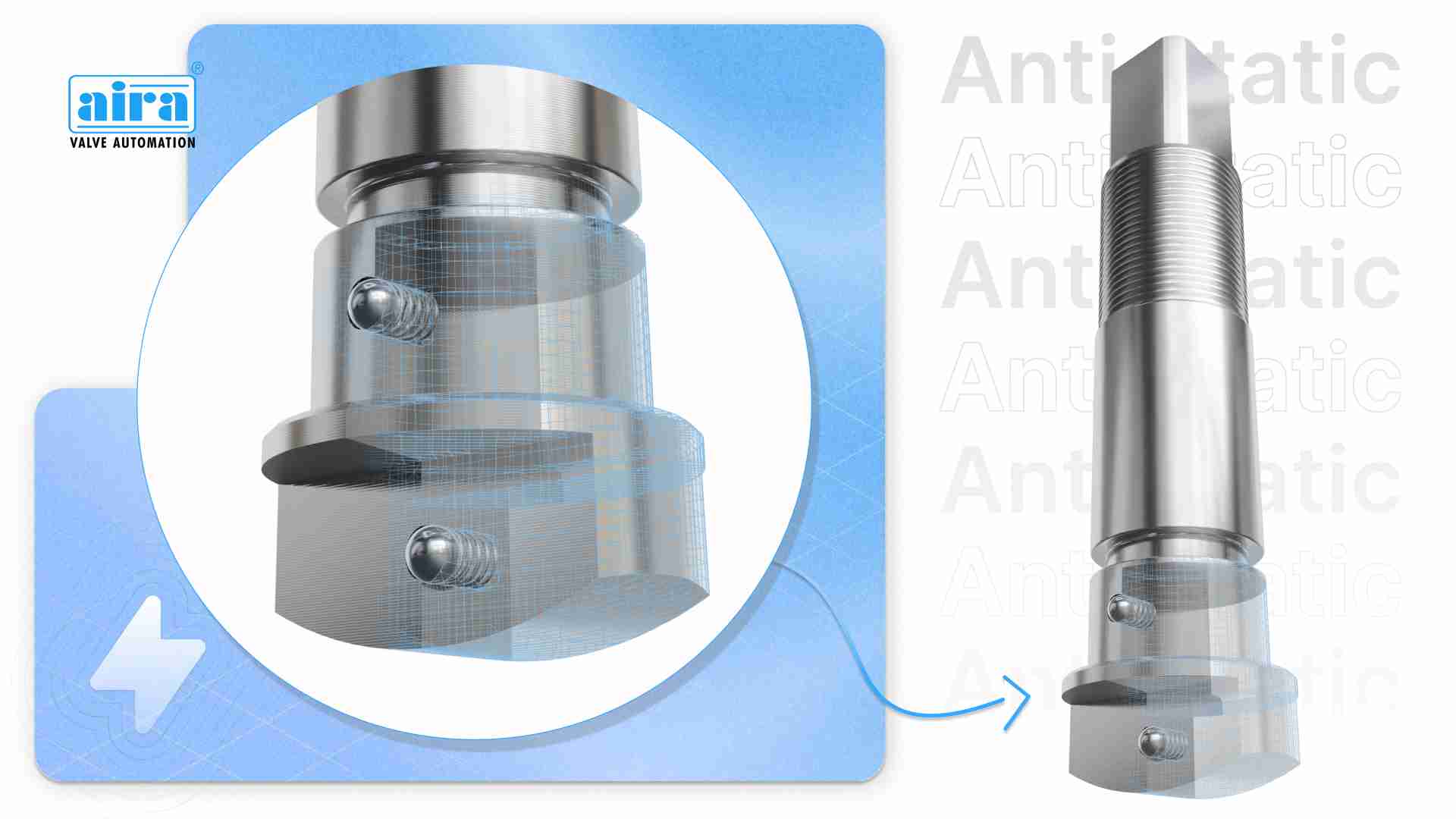

AISI 410, SS 304, SS 316, SS 304l, SS 316l, DUPLEX 2205, DUPLEX 2507, MONEL

Seat Material

SS 304, SS 316

Certification

DESIGN CE APPROVED, SIL3 APPROVED, POD

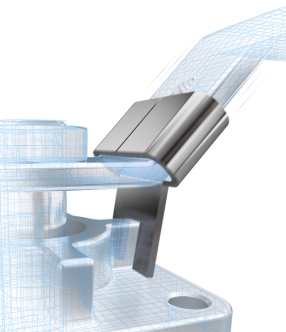

1 – Metal Seated Ball Valves Are Inherently Fire Safe And It’s Design Is Metal Anti-static By Nature Of The Metal To Metal Contact.

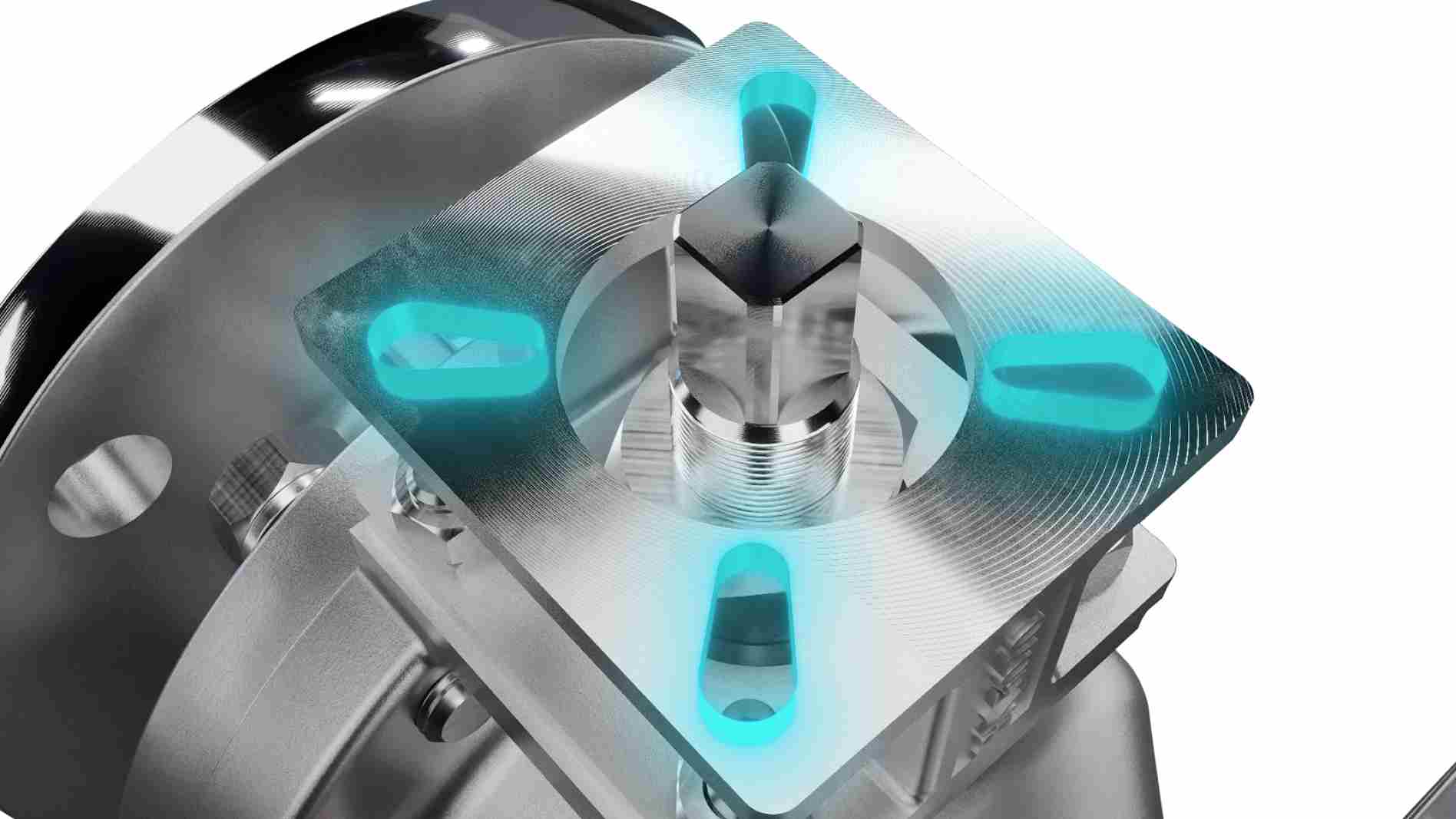

2 – Harden Face Treatment On Ball And Seats Provides The Longer Life Cycle In High Temperature Environment.

3 – Advanced Seat Structure And High Precision Ball Preparation Can Ensure Sealing Performance And Reduce The Operation Torque.

4 – Highly Precise Machining Enables The Ball And Seattight Shut-off.

5 – Suitable For Temperature Range -50°C To 500°C (-50°C To 800°C (On Request).

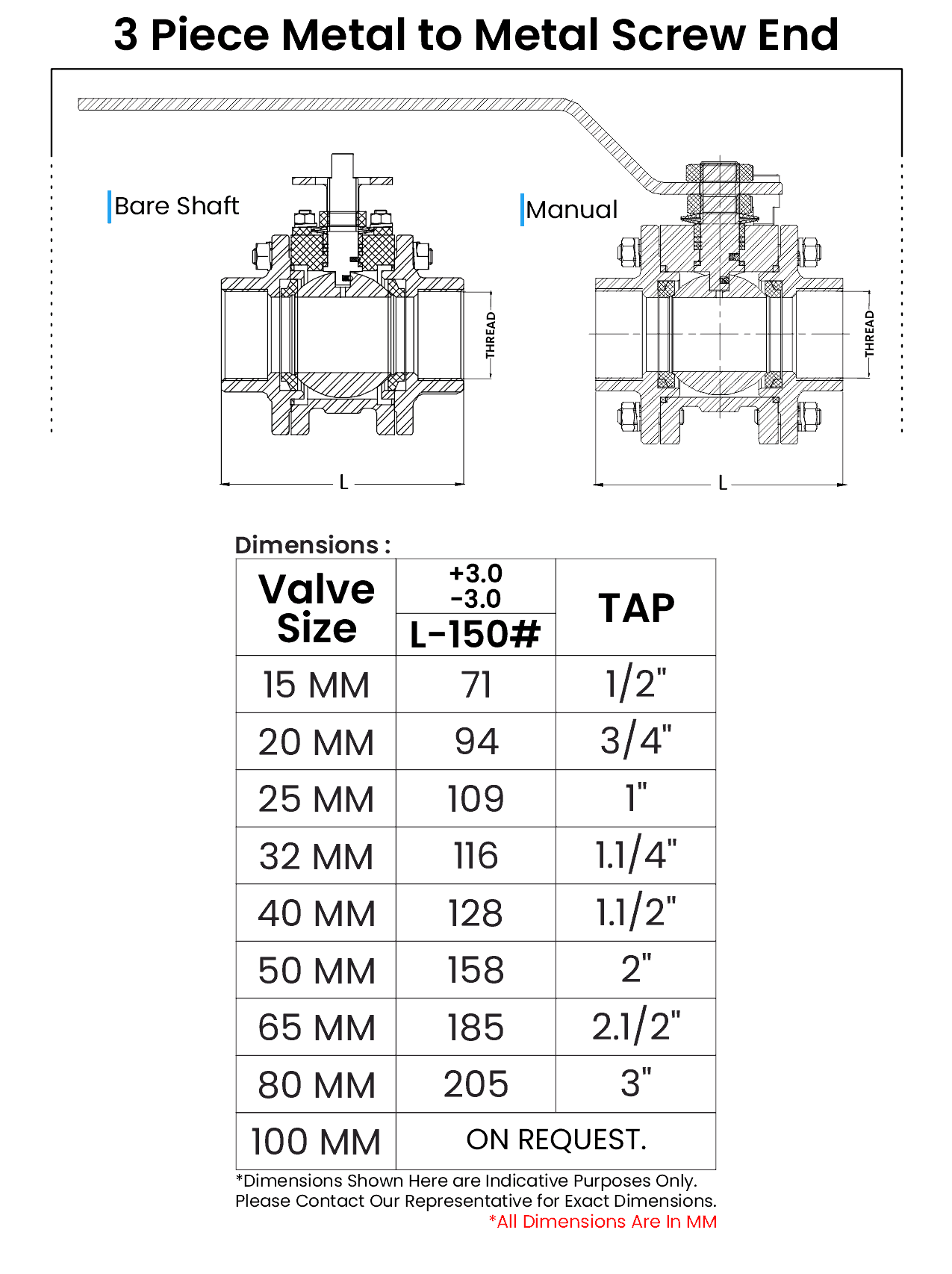

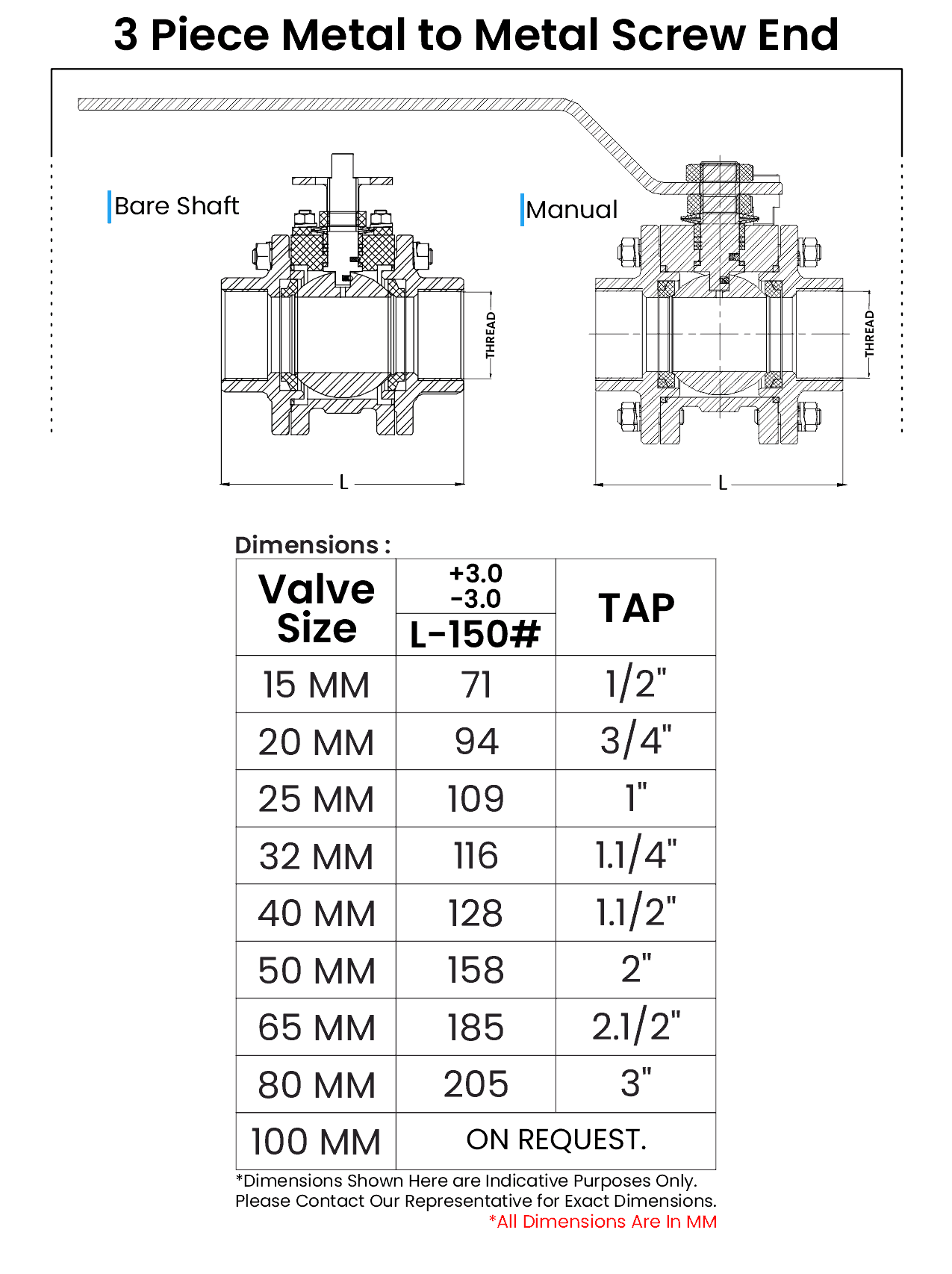

3 Piece

Metal To Metal Screwed End Ball Valve

3 Piece

Metal To Metal Screwed End Ball Valve

Dimension Table

ADDONS

Related Products

Working Days: Monday to Saturday.Tell Us How We Can Help You

Request A Quote

Complete control over products allows us to ensure our customers receive the best quality prices and service