Our advanced in-house manufacturing facility ensures complete control over the production process, enabling us to deliver precision-engineered ball valves that meet global standards. Whether you seek reliability, durability, or innovation, Aira Euro Automation is your go-to partner for high-quality ball valve solutions. Choose us to elevate your industrial operations with proven expertise.

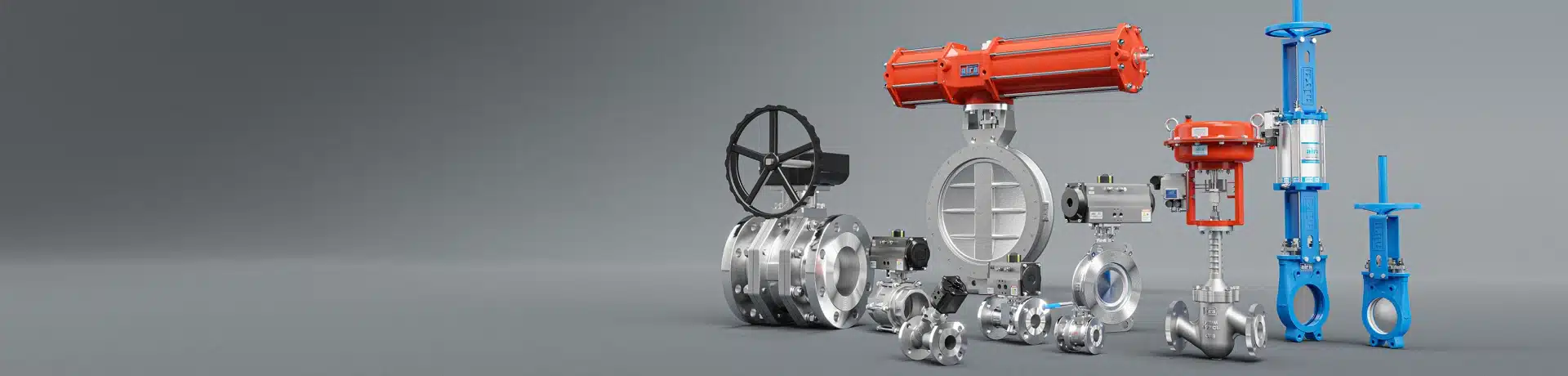

At Aira Euro Automation, we understand that every industry has unique requirements, and that’s why we manufacture a wide range of ball valves designed to handle diverse applications.

Our portfolio includes:

Aira Euro Automation offers a wide range of premium seat materials, which is perfect for your industrial requirements.

We also offer extraordinary material valves featuring D-plastic, modified PTFE, our exclusive Aira250 seal, and PEEK, designed for high temperatures up to 300°C.

Designed for pressures up to 4000 PSI and available in multiple classes-

We also offer a wide variety of end connections such as:

We are experts in making customized ball valves as per customer requirement and drawing, which is suitable for work pressures of 4000 PSI.

Aira Euro Automation takes pride in being a trusted and leading pneumatic ball valve manufacturer in India, delivering unmatched quality and reliability. Our pneumatic ball valves, also known as pneumatic actuated ball valves, are designed to enhance automation and efficiency in various industrial applications. By integrating precision engineering with advanced automation, these valves ensure seamless operation in industries like oil and gas, chemical processing, pharmaceuticals, and more.

With a wide range of models and types, including Single-Piece, 2-Piece, 3-Piece, and Trunnion-Mounted Ball Valves, we offer customized pneumatic solutions to meet your specific requirements. Manufactured using high-quality materials such as WCB, CF8, CF8M, and specialty alloys, our pneumatic ball valves are built to withstand high pressure, temperature, and demanding industrial conditions.

Choose Aira Euro Automation for reliable pneumatic ball valve solutions that optimize your processes and deliver exceptional performance every time.

Aira Euro Automation is committed to delivering high-quality ball valves that combine innovative engineering with unmatched durability.

Our ball valves are designed with a blow-out proof stem featuring a backseat to maintain sealing integrity under high pressure. Mirror-finished balls, with drilled holes, ensure longer life of the seals by relieving body cavity pressure to the upstream, preventing permanent damage caused by thermal expansion. Additionally, the anti-static feature addresses static electricity build-up, which can pose a fire hazard when handling flammable fluids. Spring-loaded balls between the ball, stem, and body ensure electrical continuity as per ISO 17292 standards, enhancing safety and reliability.

Aira gives valves with casting NDE test as per B16.34 if the customer requires it. With helium & vacuum tests & fugitive emission testing. Also, we give all the material with BS EN 10204, 3.1 & 3.2, which is the best quality.